Description

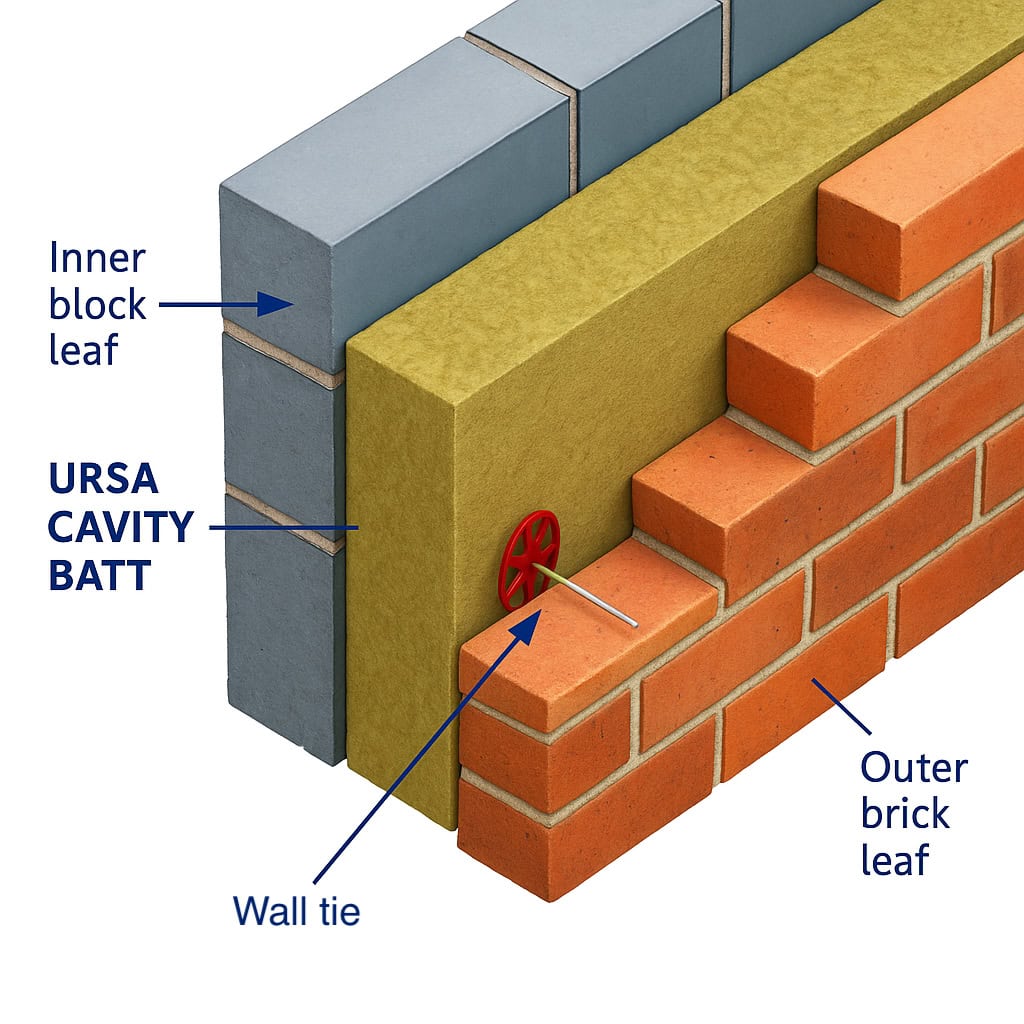

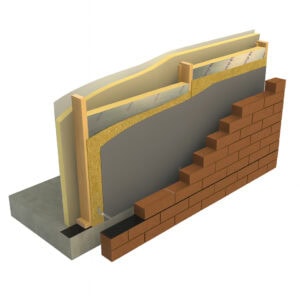

150mm URSA Cavity Batt is a lightweight, semi rigid glass mineral wool slab treated with silicon based water repellent. It is suitable for use in both fully and partially filled masonry cavity walls up to 25m high. It is manufactured from an abundant, sustainable resource and may utilise up to 80% glass waste. It is suitable for use in both fully and partially filled masonry cavity walls up to 25m high.

CHARACTERISTICS

- Excellent sound insulation,

- Enhances the acoustic comfort of the building.

- Reduces the risk of condensation,

- Provides warmer living conditions,

- May be used below the damp-proof course in order to offer a degree of edge insulation to the floor,

- Maintenance free and have an indefinite life at least equal to that of the building.

- Has minimal resistance to the passage of water vapour thus allowing the wall to breathe.

- User friendly – has the soft touch feel making it easier to handle and install whilst still maintaining its excellent mechanical properties,

- Environment friendly – Glass wool is manufactured from an abundant, sustainable resource and may utilise up to 80% glass waste,

- Zero Global Warming Potential (GWP),

- Insulation savings

- Adaptable – One product may be used for both full and partial fill systems,

- Outstanding product quality manufactured to ISO 9001 Quality Systems,

APPLICATION

- Full fill cavity systems – In any exposure zone in buildings up to 25m high.

- Partial fill cavity systems – The risk of wind driven rain penetration increases on exposed or coastal locations. The use of a residual 50mm clear cavity means URSA Cavity Batts may be used in any exposure zone. British Board of Agrment approval means that in many instances only a 25mm residual cavity need be maintained.

INSTALLATION

Full Fill Systems

The wall may be constructed leading with either leaf. It is good practice however to construct the outer leaf first as this allows the mortar joints on the cavity face to be cleaned and to check that the mortar joints are all fully filled. The URSA Cavity Batts are then installed as the wall is built.

- The leading leaf of masonry, normally the outer leaf, is built with the first row of wall ties at 600mm centres where the insulation is to begin.

- The first row of URSA Cavity Batts, cut to size if necessary, may begin below the DPC in order to offer edge insulation to the floor.

- The inner leaf is then built, normally level with the top of the URSA Cavity Batts. It is permissible to build the outer leaf one brick higher to secure the next row of slabs ensure mortar is cleaned from the cavity face.

- Raise the leading leaf to the level of the next row of wall ties, normally at 450mm vertical centres (maximum 900mm centres horizontally). Ensure that the drip is positioned at the centre of the cavity and that the ties slope down towards the outer leaf. Excess mortar should be cleaned from this leaf before fitting the URSA Cavity Batts onto the lower ties.

- The inner leaf is then built to the level of the top of the slabs and the process repeated.

- The subsequent rows of slabs should be fitted with vertical joints staggered i.e. brick bond with all joints tightly butted. Slabs with damaged edges or corners should not be used.

- As work proceeds ensure that the top edge of the URSA Cavity Batts is clean and free from mortar droppings. The use of a cavity batten will help to protect the slab edges as the next section is built.

- Cut sections of slab will be required around openings or at corners. It is essential that these be cut accurately to fill the space they are intended for and are adequately secured. Do not bend the batts around external or internal corners.

- Ensure that partially completed walls are protected from inclement weather (wind, rain and snow) and at the end of the days work.

Partial Fill Systems

Generally the inner leaf is constructed ahead of the outer leaf with the URSA Cavity Batts fastened to the cavity face of the inner leaf using the wall ties or clips. Wall ties with collars are required to hold the slabs in position. URSA Cavity Batts are 455mm wide to fit the 450mm

vertical spacing of the wall ties. The horizontal spacing may vary but should be no more than 900mm to ensure adequate retention of the slabs. Spacing of the wall ties should follow the recommendations given in BS EN 1996, Eurocode 6. To prevent rainwater penetration across the wall a minimum 25mm clear cavity must be maintained at all times. A 50mm clear cavity is inherently safer and is a requirement of NHBC Standards.

- The inner leaf is built with the first row of wall ties at 600mm centres where the insulation is to begin.

- The first row of URSA Cavity Batts, cut to size if necessary, may begin below the DPC in order to offer edge insulation to the floor.

- Raise the leading leaf to the level of the next row of wall ties, normally at 450mm vertical centres. Excess mortar should be cleaned from the inner leaf before fitting the slabs onto the lower ties and securing with a retaining collar.

- The next row of wall ties (and collars) is fitted at maximum 900mm centres to retain the tops of the slabs. Ensure that the drip is positioned at the centre of the residual cavity and that the ties slope down towards the outer leaf.

- Additional ties may be required for structural stability or to ensure adequate retention of the URSA Cavity Batts. 6. The outer leaf is then built to the level of the top of the slabs and the process repeated.

- The subsequent rows of slabs should be fitted with vertical joints staggered i.e. brick bond with all joints tightly butted. Slabs with damaged edges or corners should not be used.

- As work proceeds ensure that the top of the slabs and the residual cavity are kept clean and free from mortar droppings or other debris. The use of a cavity batten will help to protect the slab edges and keep the cavity clean as the next section is built.

- Cut sections of slab will be required around openings or at corners. It is essential that these be cut accurately to fill the space they are intended for and are adequately secured. Do not bend the batts around external or internal corners.

- Ensure that partially completed walls are protected from inclement weather (wind, rain and snow) and at the end of the days work.

CERTIFICATION

- URSA Cavity Batts achieved outstanding product quality manufactured to ISO 9001 Quality Systems.

- This product has a low reaction to fire and meets Euroclass A1 to BS EN 13501-1 standards