Kingspan K110

Kooltherm K110 is ideal when you need high-performance overhead insulation – on ceilings, soffits, or structural slabs – but do not want layers of bulky build-up. It is a slim, rigid board that packs strong thermal protection into a neat, manageable sheet.

K110 insulation is designed to stay tight to the underside of concrete or structural elements, helping reduce heat loss while keeping overall ceiling build-up to a minimum.

What Is K110 Kingspan Insulation?

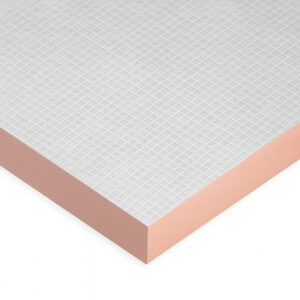

Kingspan Kooltherm K110 is built around a rigid, fibre‑free phenolic foam core. That core is lightweight yet dense, with a closed-cell phenolic insulation structure, which makes it a top performer while keeping the board manageable on site.

On one side, the foam is covered with a glass‑tissue facing (concealed inner side), and on the other side, a low-emissivity composite foil facing (exposed outer side). Both are bonded firmly to the core.

It achieves a thermal conductivity (λ‑value) of 0.019 W/m·K, putting it among the most efficient rigid insulation panels for ceilings and soffits.

Thanks to the efficient core and facings, it offers strong thin‑profile insulation, where thick walls are not necessary to achieve good thermal resistance.

What Is K110 Soffit Board Used For?

The K110 Kingspan board is primarily used in these overhead concrete and structural surfaces:

- Structural ceilings such as basements, car‑park decks, and mezzanine slabs where a solid deck above exists.

- Concrete soffits in loading bays or under buildings.

Benefits of Kingspan K110 Soffit Board

Here is why the K110 soffit board is a great pick for soffit or structural‑ceiling insulation:

- Top‑class thermal efficiency in a slim board – K110 achieves a very low thermal conductivity (~ 0.019 W/m·K), providing strong insulation without thick layers.

- Saves ceiling depth space – Its slim profile keeps soffits and ceilings neat rather than bulky, which is a big plus when head‑height or structural depth is limited.

- Rigid, stable, and easy to handle – The fibre‑free phenolic foam core is rigid yet lightweight. That makes K110 easier to cut, lift, and repair than many alternatives for soffit or concrete‑slab insulation.

- Resistant to moisture and air leakage – K110 withstands vapour and air movement quite well when installed according to manufacturer guidelines. So its insulating properties are reliable over time.

- Fire performance and safety assurance – The board is FM‑approved to Class 1 (FM 4880) when installed correctly with recommended fixings, foil orientation, and taped joints, making it suitable for residential or commercial ceilings and soffits that need compliance.

- Durable and long‑lasting – When properly fixed and not exposed to damaging solvents, K110 will maintain its insulation properties for many years – a solid long-term investment for ceilings, basements, car parks, and other concrete soffit areas.

Why Choose Our K110 Kingspan Insulation?

Here’s why Insulation Wholesale is a builder’s go-to choice for Kingspan K110 soffit board:

- Durable, authentic boards – Every K110 board we sell is genuine Kingspan, giving you long-lasting performance you can trust.

- Competitive pricing – We bring you premium soffit and ceiling insulation at low prices.

- Pallet deals and volume discounts – Perfect for bigger projects, so you save more when buying in bulk.

- Fast, reliable UK delivery – Boards arrive on time, keeping your project moving.

- Expert support – Our team can advise on quantities, fixing, and offer installation tips.

- Flexible ordering – Buy a single board for a small job or full pallets for a large site. We’ve got you covered.

Upgrade your ceilings with K110 and enjoy durable Kingspan insulation. Whether you need a bulk or single board order, we provide fast quotations and deliver quickly across the UK.

FAQ

Where to buy Kingspan K110?

You can pick up your Kingspan Kooltherm K110 plus soffit board directly from Insulation Wholesale. We stock genuine K110 at competitive prices. Order Kooltherm K110 online today, and we will ship straight to your site.

How much is K110 Kingspan soffit board?

A 2.4 m × 1.2 m K110 board typically costs £85–£110 for standard soffit‑board thicknesses. The final price depends on the board thickness, how many boards you order (bulk buying can reduce the unit cost), and supply‑chain factors, so exact costs may shift. Ask Insulation Wholesale for the latest quote.

How to fit Kingspan K110 insulation?

- Cut through your Kooltherm K110 panels using a sharp knife or fine-toothed saw. Use a straight edge as your guide.

- Position the boards tightly against the soffit, keeping all edges close together.

- Use at least 11 mechanical fixings per 2.4 m × 1.2 m board, and spread them evenly.

- Keep fixings 50–150 mm from edges and corners; avoid joints.

- Tape all board joints and exposed edges with 70 mm+ self-adhesive foil tape.

- Handle boards carefully – store them in a dry place and off the ground.

- Work systematically across the area to maintain a continuous insulation layer.

- Check that each board is fully supported and level before moving on.

Showing all 2 results

-

70mm Kingspan Kooltherm K110 Soffit Board Insulation 2400mm x 1200mm Pack of 4 (11.52m2)

70mm Kingspan Kooltherm K110 Soffit Board Insulation enhances thermal performance in soffit areas with its slim, efficient design. It’s easy to install and improves energy efficiency.

£318.22£381.86 Ex VATInc VAT£27.62£33.14 Per M2 Add to cart -

90mm Kingspan Kooltherm K110 Soffit Board Insulation 2400mm x 1200mm Pack of 3 (8.64m2)

90mm Kingspan Kooltherm K110 Soffit Board Insulation enhances thermal performance in soffit areas with its slim, efficient design. It’s easy to install and improves energy efficiency.

£297.71£357.25 Ex VATInc VAT£34.46£41.35 Per M2 Add to cart