Description

- In compliance with the new building regulations Approved Document E 2003

- Approved by NHBC for ADE 2003 compliance

- Excellent impact and airborne performance

- Offers long-term performance without collapse or bottoming out under high point loads

- Minimal creep even under high loads

- Resistant to ageing and deformation

- Quick and easy to install

- No need for separate perimeter strips

- Minimises construction heights

- High quality and exact material thickness guaranteed

- Suitable for use with under floor heating

- Protects expansion joints

- Sustainable and completely recyclable

- Mildew and moisture proof

- Zero global warming potential (GWP)

- Zero ozone depletion potential (ODP)

APPLICATION

Ideally suited where superior and cost effective impact sound control is required.

- Apartments,

- Hotels,

- Retail,

- Education Buildings

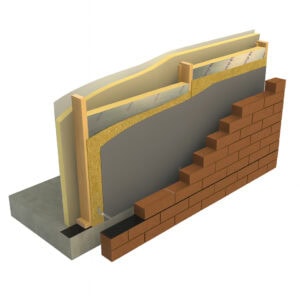

INSTALLATION

- It is important that the base floor is clean (free from loose dirt and concrete dust). Flat (within National Building Standards +5mm over a 5m span) and where possible, dry.

- A sharp craft knife and straight edge must be used for cutting to size. Perimeter edges, joints must be overlapped. The overlap must be at least 50mm and taped down using Regupol Hi-tack tape Turn up at all perimeter edges.

- The Acoustic Resilient Layer should sit above the finished screed height ensuring that there is sufficient material available to lap under all wall linings and skirting boards (> 75mm).

- Lay a waterproof membrane, minimum of 0.2mm thick over the entire area. This must be overlapped by at least 100mm and must also cover the upturned edges.

- All joints must be taped to prevent movement during the casting process.

TECHNICAL

- Thickness: 5mm

- Width: 1150mm

- Length: 2250mm

- Coverage: 2.58m2

- Density: 720kg/m3

- Weight/m2: 3.6kg

- Weight: 9.32kg

- Airbourne sound insulation: 49dB

- Impact Sound Insulation: 46dB