Plastic Render Beads

When working with render, plastic beads help keep everything straight, strong, and tidy. They are the little guides that prevent uneven edges and help reduce cracking along the edges later on.

What is PVC render bead?

A PVC render bead is a small plastic profile that helps shape, straighten, and protect the edges of a render coat. It is the guiding strip that keeps the finish neat and gives the render something reliable to work against.

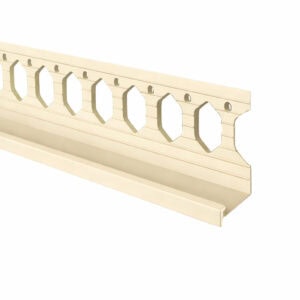

Plastic render beads are made from rigid, weather-resistant material. They usually have a straight spine in the middle and perforated wings on each side. When pressed into adhesive or fresh render, the wings bond securely into the render, and the spine creates a clean line – whether that is a corner, an edge, or a stop point.

What is plastic rendering bead used for?

Here’s how each type of PVC render bead is used:

1. Making corners straight and tough

When working on an exposed corner – like the edge of a house wall, a pillar, or the corner of a window reveal – builders use a PVC angle bead. Corners are the first places to get knocked by ladders, wheelbarrows, or bags of gear.

These beads are used on:

- External building corners

- Window and door reveals (depending on system design)

- Porch pillars and chimney edges

- Edges of garden walls or boundary walls

The plastic angle bead anchors into the render and gives a perfect straight line to skim to, so you are not guessing the shape.

2. Ending the render neatly

If the render needs to stop at a certain point, a PVC stop bead gives a clean finish line. Without a stop bead, the edge can look ragged or extend onto another surface.

Where they are used:

- Around window frames

- Around door frames

- Where render meets brickwork

- On half-rendered walls (top half rendered, bottom half cladding or brick)

- When rendering up to a downpipe or soil pipe

The beads provide the termination point for the render.

3. Diverting water away from the wall

The protruding lip of the plastic bellcast bead (also called a drip bead) directs rainwater away from the wall so it does not streak or stain the render.

Where they are used:

- Bottom of exterior walls

- Above DPC on houses

- Above windows to stop drips running down

- On top of plinths or ledges

They stick out slightly, creating a tiny lip that diverts water off the wall.

4. Providing flexibility for large walls

Long walls or tall façades need movement beads. A movement bead is like a small expansion joint, allowing render to stretch without cracking.

Where they are used:

- Long runs of render where the wall has no natural breaks

- Multi-storey façades

- Large gable ends

- Areas exposed to significant temperature swings

They allow the render to slightly expand and contract so it stays intact over time.

5. Keeping thin-coat systems straight

When using thin-coat renders (silicone, acrylic, or EWI systems), thin coat beads are fitted around edges and openings.

Where they are applied:

- External wall insulation (EPS/XPS/MW board systems)

- Silicone or acrylic render jobs

- Thin skim layers around doors and windows

- Edges of decorative bands or architectural features

They match the shallow depth, so the finish stays even and smooth.

6. Reinforcing stress points and weak areas

When a wall needs more strength – especially in external wall insulation – PVC mesh reinforced beads are used.

Typical uses:

- Strengthening the corners of insulation boards

- Reinforcing around openings (windows, door heads, sills)

- Protecting board joints

- Adding toughness to vulnerable areas on façades

The mesh gives the render something solid to grab onto.

Types of plastic skim bead

Here are the six main types of uPVC plastic beads:

1. Plastic angle beads (corner beads)

These are the beads installed on corners – the places that get hit, scraped, or knocked the most. The bead sits on the corner like a protective shell and gives a perfectly straight line to follow with render. It keeps corners crisp instead of crumbly.

2. Plastic stop beads

A stop bead is what builders use when the render needs to end cleanly. It acts like a “full stop” for the coat. They are found around door frames, window edges, or anywhere the render should not continue. They keep the edges neat so the finish does not look messy or overrun.

3. Plastic bellcast beads (drip beads)

These sit along the bottom of an exterior wall. Their purpose is to help rainwater drip away instead of running down the surface and leaving stains. They divert the water at a slight angle so the wall stays cleaner for longer.

4. Plastic movement beads (expansion beads)

Buildings do not stay perfectly still – they shift a tiny bit with heat, cold, and settling. Movement beads give render a small “flex zone” so it can move without cracking. Use these on big walls without natural breaks or long stretches of render where things need a bit of give.

5. PVC Thin coat beads

These are made for modern, thin-layer renders like silicone or acrylic. Because these systems use shallow coatings, they need a slim bead that matches that depth. Thin coat beads help keep the edges sharp without wasting material or building the coat thicker than it should be.

6. PVC mesh beads

These beads come with mesh wings on either side. They are excellent for strengthening corners or joints in systems like external wall insulation. The mesh helps the render grip and adds extra toughness, which stops cracks from forming where the wall is under stress.

FAQ

Where to buy plastic render beads?

You can purchase plastic render beads directly from Insulation Wholesale. We stock a full range of plastic skim beads – corner trims, stop beads, bellcasts, movement joints, and more – all from reliable trade brands. Whether you just need a couple of lengths for a small job or a bundle for an entire elevation, you can order it online in a few clicks. Prices are competitive, stock is UK-held, and delivery is fast, so you can get the beads on site without any trouble.

How to fix plastic render beads?

- Get the surface ready. Dust the surface and scrape off any flaky bits.

- Measure the run. Hold the bead up where it will be fitted, check the length, and mark your cut.

- Cut the bead to the correct size.

- Fix the bead to the wall. You can use adhesive dabs, a thin ribbon of render, or

external wall insulation adhesive (for EWI systems). Most installers press the bead into a line of adhesive and adjust slightly until it is positioned correctly. The bead should sit flush, not buried or floating. - Check the line. Before anything sets, step back and look at the bead from different angles. A bead that is even slightly crooked will show through the finish coat, so this is the moment to fix it.

- Fix around corners and openings carefully.

- Apply the render over the top. Once the bead is secure, start covering it with base coat or skim. Your trowel will naturally glide along the bead and use it as a guide.

- Smooth and level the surface, then leave it to set.

How to cut plastic render beads?

Measure the length you need, and then, using tin snips or aviation snips, or plastic-compatible shears, cut slowly so the bead does not crack. Keep the wings intact, and if any curls in, straighten using fingers. Trim the ends to get neat corners.

How to stick plastic render beads?

1. For external corners on wall returns, pillar edges, or reveals that stick out

Dab or run a thin line of render or thin coat adhesive along the corner. Press the bead onto the corner so both wings sit flat against each face. Give it a gentle squeeze so the adhesive grabs through the perforations. Check that it is plumb with a level.

2. For window and door reveals (stop beads or thincoat stop beads)

Apply small dabs of adhesive down the reveal, spacing them so the bead does not wobble. Push the stop bead in so its nose lines up neatly with the window or door frame. Wipe off any squeeze-out so it does not interfere with the sealant later.

3. For end-of-run areas (end stop beads)

Put a slim line of adhesive behind the bead. Press it into position so the nose projects the correct depth for your final render thickness. Use a straightedge to make sure the bead is not bending or curving.

4. For movement joints (expansion beads)

Mark the exact line of the expansion joint on the wall first. Apply two rows of adhesive – one for each wing of the bead. Press the bead in so the central strip sits directly over the joint line. Make sure the wings are perfectly aligned so the joint works properly.

5. For the base of the wall/starter level (Bellcast Beads)

These control the base level of the render and throw rainwater clear of the wall.

Put adhesive along the base track area or just above the DPC line. Press the bead into position and check that it is dead level – this sets the entire render height. A quick tap along the length keeps it straight.

6. Below Windows, Drip Edges, Eaves (Drip Beads)

Drip beads stop water from running back into the wall – they force it to fall straight off.

Run adhesive along the area where the drip will sit. Press the bead into place, making sure the lip is pointing outward to kick water away. Double-check to ensure it is level – a misaligned drip edge is noticeable and less effective.

Showing all 15 results

-

10mm Ivory Plastic Angle Bead 2.5m Pack of 50

10mm Ivory Plastic Angle Bead / Corner bead for use on all external/internal rendering and plastering applications. Plastic Angle Beads are applicable for corners where a strong, true and sharp corner is needed.

£135.33£162.40 Ex VATInc VAT£2.71£3.25 Per Unit Add to cart -

10mm Ivory Plastic Bellcast Bead 2.5m Pack of 50

10mm Ivory Bellcast beads also known as drip beads are designed for function and speed on all external rendering applications. Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£135.33£162.40 Ex VATInc VAT£2.71£3.25 Per Unit Add to cart -

10mm Ivory Plastic Movement Bead 2.5m Pack of 50

10mm Ivory Plastic Movement Bead/ expansion joints are designed for areas of render over 20 square metres and should be specified every 4-6 metres, over structural movement joints and changes of background. . Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£259.29£311.15 Ex VATInc VAT£5.19£6.23 Per Unit Add to cart -

10mm Ivory Plastic Stop Bead 2.5m Pack of 50

The Ivory Plastic Stop Beads are designed for function with all standard rendering and internal plastering applications, external wall insulation, timber frame, and other weatherboard systems. Provides a straight edge and stop to the render at changes of finish and up to doors and windows.

£135.33£162.40 Ex VATInc VAT£2.71£3.25 Per Unit Add to cart -

10mm White Plastic Angle Bead 2.5m Pack of 50

10mm White Plastic Angle Bead / Corner bead for use on all external/internal rendering and plastering applications. Plastic Angle Beads are applicable for corners where a strong, true and sharp corner is needed.

£118.71£142.45 Ex VATInc VAT£2.37£2.84 Per Unit Add to cart -

10mm White Plastic Bellcast Bead 2.5m Pack of 50

10mm White Bellcast beads also known as drip beads are designed for function and speed on all external rendering applications. Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£118.71£142.45 Ex VATInc VAT£2.37£2.84 Per Unit Add to cart -

10mm White Plastic Movement Bead 2.5m Pack of 50

10mm White Plastic Movement Bead/ expansion joints are designed for areas of render over 20 square metres and should be specified every 4-6 metres, over structural movement joints and changes of background. . Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£225.21£270.25 Ex VATInc VAT£4.50£5.40 Per Unit Add to cart -

10mm White Plastic Stop Bead 2.5m Pack of 50

The White Plastic Stop Beads are designed for function with all standard rendering and internal plastering applications, external wall insulation, timber frame, and other weatherboard systems. Provides a straight edge and stop to the render at changes of finish and up to doors and windows.

£118.71£142.45 Ex VATInc VAT£2.37£2.84 Per Unit Add to cart -

15mm Ivory Plastic Angle Bead 2.5m Pack of 50

15mm Ivory Plastic Angle Bead / Corner bead for use on all external/internal rendering and plastering applications. Plastic Angle Beads are applicable for corners where a strong, true and sharp corner is needed.

£140.38£168.46 Ex VATInc VAT£2.81£3.37 Per Unit Add to cart -

15mm Ivory Plastic Bellcast Bead 2.5m Pack of 50

15mm Ivory Bellcast beads also known as drip beads are designed for function and speed on all external rendering applications. Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£134.74£161.69 Ex VATInc VAT£2.69£3.23 Per Unit Add to cart -

15mm Ivory Plastic Movement Bead 2.5m Pack of 50

15mm Ivory Plastic Movement Bead / expansion joints are designed for areas of render over 20 square metres and should be specified every 4-6 metres, over structural movement joints and changes of background. . Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£276.25£331.50 Ex VATInc VAT£5.53£6.64 Per Unit Add to cart -

15mm Ivory Plastic Stop Bead 2.5m Pack of 50

The Ivory Plastic Stop Beads are designed for function with all standard rendering and internal plastering applications, external wall insulation, timber frame, and other weatherboard systems. Provides a straight edge and stop to the render at changes of finish and up to doors and windows.

£140.38£168.46 Ex VATInc VAT£2.81£3.37 Per Unit Add to cart -

15mm White Plastic Movement Bead 2.5m Pack of 50

15mm White Plastic Movement Bead / expansion joints are designed for areas of render over 20 square metres and should be specified every 4-6 metres, over structural movement joints and changes of background. . Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£240.36£288.43 Ex VATInc VAT£4.81£5.77 Per Unit Add to cart -

15mm White Plastic Stop Bead 2.5m Pack of 50

The White Plastic Stop Beads are designed for function with all standard rendering and internal plastering applications, external wall insulation, timber frame, and other weatherboard systems. Provides a straight edge and stop to the render at changes of finish and up to doors and windows.

£122.20£146.64 Ex VATInc VAT£2.44£2.93 Per Unit Add to cart -

15mm White Plastic Bellcast Bead 2.5m Pack of 50

15mm White Bellcast beads also known as drip beads are designed for function and speed on all external rendering applications. Discreet but strong, all beading gives a perfect finish to through colour render and is equally suitable for sand and cement.

£119.08£142.90 Ex VATInc VAT£2.38£2.86 Per Unit Get restock alert