Wall Lining System

A wall lining system is a layer added to an internal wall to provide a stable, smooth surface for the final finish. Before adding paint or tiles to a wall, you have to make sure there is something solid behind it. This is the purpose of a dry lining system.

What Is Dry Lining System?

Drylining systems for walls provide a fast and efficient method to create smooth, level walls. The system is fast, cleaner than wet plaster, and it gives a wall that reliably performs as expected.

In drylining, plasterboard panels are fastened onto metal and timber wall frames to create a flat, stable surface. If using moisture– or fire-rated boards, a primer or sealer will give the finish an extra edge.

When drylining is done right:

- The wall stays straight and flat over time.

- Tiles, paint, or wallpaper do not crack or come off easily because the surface is solid.

- The wall keeps heat in and sound out if insulation or acoustic boards are included.

- In wet areas, the wall resists damp and mould.

What Is Metal Wall Lining System Used For?

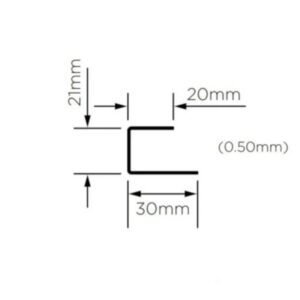

A metal wall lining system is essentially a drylining setup that uses a lightweight metal framework instead of timber, suitable for durability and fire or moisture-rated applications. The boards (usually plasterboard or specialist panels) are fixed to lightweight steel channels anchored slightly away from the existing wall.

Metal wall lining is used in:

- Refurbishments and wall straightening.

- Moisture-prone areas such as basements, bathrooms, and kitchens using appropriate moisture-resistant boards.

- Fire- and acoustic-rated assemblies in commercial interiors and fit-outs.

- Projects that need a clean internal face without disturbing the existing wall.

- Concealing services and improving insulation performance.

Types Of Wall Lining Systems

Wall lining systems can be grouped by installation method.

1. Direct Fix / Direct Bond (Dot & Dab)

Boards are stuck straight onto masonry using adhesive. Suitable for fast, slim wall construction with minimal framing.

Examples: Knauf Wallboard and Unilin XT/TL, which are plasterboard sheets ideal for direct bonding to walls.

2. Timber Stud Lining

Boards are fixed to timber battens, a common method in smaller projects and refurbishments where working with timber is easier or more familiar.

Examples: Many standard plasterboards from Knauf, British Gypsum, and other brands.

3. Metal Frame Wall Lining (Independent or Fixed)

Lightweight steel channels form a free-standing or partially fixed frame. Used in commercial fit-outs, bathrooms, basements, and any job where it is essential to ensure accuracy and moisture resistance, or to straighten uneven walls.

Examples: GypLyner (Gypframe) and Knauf plasterboards for steel framing.

4. Specialist Lining Systems

This covers boards designed for specific duties:

- Moisture-resistant linings

- Tile backer boards

- Fire-rated linings

- Acoustic linings

These provide performance beyond standard plasterboard.

Examples: Knauf, British Gypsum, and Siniat specialist boards for wet rooms, fire walls, and sound-sensitive areas.

Why Choose Our Wall Lining System?

This is why Insulation Wholesale is a trusted supplier of wall lining systems in the UK:

- Trusted Quality – Meets UK building standards for durability and performance.

- Versatile Options – Timber, metal, and specialist systems for any internal wall project.

- Easy Installation – Lightweight boards and simple fixings for faster installation.

- Low Prices – Competitive pricing with pallet deals.

- Expert Support – Expert guidance available for DIYers and trades.

- Fast UK Delivery to keep your project on schedule.

Order your wall lining system today and create smooth, durable walls in record time. Buy from Insulation Wholesale and enjoy expert support, best prices, and fast UK delivery.

FAQ

Where to buy wall lining systems?

You can get your wall lining system directly from Insulation Wholesale. We keep a wide range of UK stock – boards and accessories – all at competitive prices. We deliver nationwide, fast and reliably.

What is required for a full wall lining system?

Here are the wall lining products needed for a full wall lining system:

- Framework – timber battens or metal studs to which the boards will be attached.

- Insulation and services (optional) – thermal or acoustic insulation. Electrical wiring, plumbing, or pipework can be run in the cavity before fixing boards.

- Wall lining boards.

- Fixings – suitable screws or nails and special fasteners if using heavier panels.

- Joint treatment – joint tape or mesh, joint compound, filler, or setting plaster.

- Finishing (optional) – primer and sealer, plaster skim, finish coat, and decorative finishes.

How to fix wall lining system?

- Clean the wall

- Install the framework – Fix vertical battens to the wall using suitable screws, nails, or plugs. Install metal tracks on the floor and ceiling, then insert vertical studs at recommended centres. This is usually 600 mm for standard plasterboard, and 400 mm for heavy or fire-rated boards.

- Fit insulation and services if needed.

- Fix the boards:

- Timber: standard plasterboard screws.

- Metal: self-tapping drywall screws.

- Heavy boards (cement or fire-rated): longer or more robust screws.

- Apply corner beads to external corners, the tape joints, or apply mesh. Cover with joint compound and allow to dry before sanding.

- Sand the surface to remove imperfections; apply primer or sealer if needed.

Showing all 11 results