Kingspan TP10

Included in a wide range of Insulation Wholesale materials is Kingspan thermapitch insulation board. With top-notch insulation features, Kingspan TP10 thermapitch insulation has become a go-for option for most homeowners. Insulation Wholesale is here to make homeowners’ dreams come true by providing thermapitch TP 10 at affordable prices.

However, not all people understand what Kingspan thermapitch TP 10 is since it is a relatively new insulation material in the market. If you are in that category, don’t panic; here are vital aspects to know about Kingspan thermapitch.

What is a Kingspan TP10 Thermapitch Insulation?

Kingspan thermapitch TP10 is high-performance insulation consisting of fibre-free closely-tight thermoset polyisocyanurate (PIR) core.

This PIR insulation board is ideal for slated or tiled pitched warm room spaces and brings with it a thermal conductivity of 0.022 W/mK.

Kingspan PIR is available in the most common thicknesses. You can get the following thicknesses from most manufacturers; 20mm, 25mm, 30mm, 40mm, 50mm, 60mm, 70mm, 75mm, 80mm, 90mm, 100mm, 105mm, 120mm, and 150mm.

You can also get the following custom orders;45mm, 55mm, 65mm, 85mm, 110mm, 115mm, 130mm, 135mm, and 140mm.

Product Applications

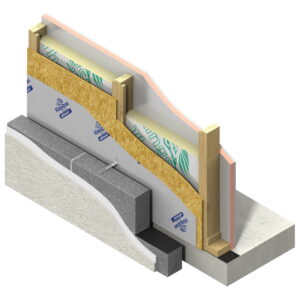

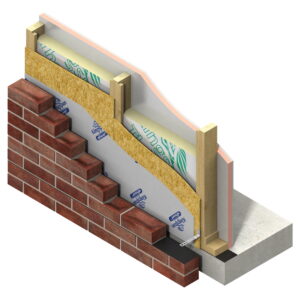

Kingspan thermapitch TP10 or Kingspan TP10 consists of high-performance compact polyisocyanurate panels utilised for rafter level insulation of slated or tiled pitched warm roof spaces.

Kingspan TP10 insulation boards are engineered with low-emissivity foil on both sides. The foil is highly resistant to moisture transmission.

Note: For suitability emphasis on ThermalFloor TF70, Thermapitch TP10, and ThermaWall TW55, Kingspan decided to brand the same product using the mentioned three names.

The popular applications of Kingspan thermapitch TP10 include:

It is used over and between rafters, under and between rafters, between rafters and, pitched roof sarking.

Characteristics of Kingspan TP10 Thermapitch Insulation

The following are key characteristics of thermapitch TP10:

- The front facings – Kingspan TP10 comes with low emissivity composite foil on both sides. This material is highly resistant to water vapour transmission. This low emissivity surface contributes to the enhanced thermal resistance of the cavity where the panel is placed.

- The core – TP10 core is manufactured from a high-performance CFC free PIR based formulation. Kingspan thermapitch TP10 has a density of 32kg/m3. It doesn’t have CFCs or HCFCs, and therefore it has zero ozone depletion potential. (ODP)/

- Compression strength – Typically, the compression strength of Kingspan thermapitch is >140kPa when subjected to BS EN 826: 1996.

- Water vapour resistance – engineered to include board facings, thermapitch TP10 attain vapour resistance greater than 100MN.s/g, when tested in adherence to BS 4370-2: 1993.

- Durability – if the application is done correctly, TP10 has an indefinite lifespan. However, this depends on conditions of use and supporting structure.

- Resistance to fungi, rodents and solvents – the insulation core isn’t vulnerable to contact with petrol and most alkalis, acids and mineral oils. However, before installing the boards, any spills should be thoroughly cleaned. However, the insulation core is vulnerable to some solvent-based adhesives, especially those with methyl ethyl ketone. As such, adhesives that contain such solvents should be avoided.

Kingspan Thermapitch TP10 Advantages

- Excellent performance rigid PIR thermoset insulation.

- No risks of condensation.

- Easy to install and handle.

- Suitable for new as well as refurbishment projects.

- Non-deleterious material.

- Resistant to water vapour transmission.

- CFC/HCFC free with zero ODP.

- No need to insulate tanks and pipes.

- Is not affected by air movement.

FAQ

Where to buy Kingspan TP10?

Get your Kingspan TP10 from Insulation Wholesale. We stock a full selection of insulation boards, including TP10 (and the related TF70 and TW55), so you have plenty of choice for different jobs.

Our pricing is competitive – because we supply wholesale and bulk orders, you can often get trade discounts, which helps if you are doing a full roof or a larger project. Just send in your dimensions or project details, and we will provide a fast quote with fast nationwide delivery available.

Can Kingspan TP10 be used for floor insulation?

Yes, you can use Kingspan TP10 for floor insulation. TP10, TF70, and TW55 are technically similar PIR boards designed for different applications, with minor variations on certification and facings depending on the intended use. That is, TP10 for pitched roofs, TF70 for floors, and TW55 for timber and steel frames. But the core product is the same material.

When you buy a pallet, the packaging may be labelled TP10/TF70/TW55, which indicates that the items are interchangeable. So, TP10 can be used in floor build-up, just as you would TW55, provided it meets the project specifications. Just follow the correct floor installation steps – level the substrate, stagger joints, and use appropriate fixings or screed.

Can you cut TP10 insulation?

Yes, you can cut Kingspan Therma TP10 insulation.

- Outline the cut line: Use chalk or a pencil to mark the cut area.

- Tools to use: To cut thin or moderately thick Kingspan TP10 panels, use a sharp handsaw, fine-toothed saw, or insulation knife. A circular saw with a fine blade will give a neat edge on thicker panels like the Kingspan TP10 100mm.

- Score & snap (thinner TP10 insulation): Boards up to ~40 mm thick can be lightly scored on both sides with a utility knife, then snapped along the line.

- Support the boards: Place each Therma TP10 on a flat surface or batten to get even cuts.

- Safety: Protect yourself from PIR dust using gloves, a dust mask, and goggles.

How much is Kingspan Thermapitch TP10 insulation?

It is difficult to pin down a single price for Kingspan Thermapitch TP10, since it varies with thickness and pack size. On average, though, TP10 typically ranges from approximately £2.80–£3.50 per m² for thin 25–50mm boards in bulk packs, up to £9–£15 per m² for thicker, smaller-coverage packs.

Showing all 15 results

-

100mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

All three models 100mm Kingspan Therma PIR Insulation Board:

- 100mm Thermapitch TP10

- 100mm Thermafloor TF70

- 100mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£138.93£166.72 Ex VATInc VAT£16.08£19.30 Per M2 Add to cart -

120mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 120mm Kingspan Therma PIR Insulation Board:

- 120mm Thermapitch TP10

- 120mm Thermafloor TF70

- 120mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£111.30£133.56 Ex VATInc VAT£19.32£23.18 Per M2 Add to cart -

125mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 20mm Kingspan Therma PIR Insulation Board:

- 125mm Thermapitch TP10

- 125mm Thermafloor TF70

- 125mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£128.56£154.27 Ex VATInc VAT£22.32£26.78 Per M2 Add to cart -

140mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 140mm Kingspan Therma PIR Insulation Board:

- 140mm Thermapitch TP10

- 140mm Thermafloor TF70

- 140mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£139.15£166.98 Ex VATInc VAT£24.16£28.99 Per M2 Add to cart -

150mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 150mm Kingspan Therma PIR Insulation Board:

- 150mm Thermapitch TP10

- 150mm Thermafloor TF70

- 150mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£139.42£167.30 Ex VATInc VAT£24.20£29.04 Per M2 Add to cart -

25mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 12 (34.56m2)

All three models 25mm Kingspan Therma PIR Insulation Board:

- 25mm Thermapitch TP10

- 25mm Thermafloor TF70

- 25mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£213.03£255.64 Ex VATInc VAT£6.16£7.39 Per M2 Add to cart -

30mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 10 (28.8m2)

All three models 30mm Kingspan Therma PIR Insulation Board:

- 30mm Thermapitch TP10

- 30mm Thermafloor TF70

- 30mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£209.90£251.88 Ex VATInc VAT£7.29£8.75 Per M2 Add to cart -

40mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 8 (23.04m2)

All three models 40mm Kingspan Therma PIR Insulation Board:

- 40mm Thermapitch TP10

- 40mm Thermafloor TF70

- 40mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

Non-refundable.

£191.42£229.70 Ex VATInc VAT£8.31£9.97 Per M2 Add to cart -

50mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 154.836m (8′ x 4′) Pack of 6 (17.28m2)

All three models 50mm Kingspan Therma PIR Insulation Board:

- 50mm Thermapitch TP10

- 50mm Thermafloor TF70

- 50mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£159.59£191.51 Ex VATInc VAT£9.24£11.09 Per M2 Add to cart -

60mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 5 (14.40m2)

All three models 60mm Kingspan Therma PIR Insulation Board:

- 60mm Thermapitch TP10

- 60mm Thermafloor TF70

- 60mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£165.00£198.00 Ex VATInc VAT£11.46£13.75 Per M2 Add to cart -

70mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 4 (11.52m2)

All three models 70mm Kingspan Therma PIR Insulation Board:

- 70mm Thermapitch TP10

- 70mm Thermafloor TF70

- 70mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£143.09£171.71 Ex VATInc VAT£12.42£14.90 Per M2 Add to cart -

75mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 4 (11.52m2)

All three models 75mm Kingspan Therma PIR Insulation Board:

- 75mm Thermapitch TP10

- 75mm Thermafloor TF70

- 75mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£149.53£179.44 Ex VATInc VAT£12.98£15.58 Per M2 Add to cart -

80mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 4 (11.52m2)

All three models 80mm Kingspan Therma PIR Insulation Board:

- 80mm Thermapitch TP10

- 80mm Thermafloor TF70

- 80mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£164.58£197.50 Ex VATInc VAT£14.29£17.15 Per M2 Add to cart -

90mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

All three models 90mm Kingspan Therma PIR Insulation Board:

- 90mm Thermapitch TP10

- 90mm Thermafloor TF70

- 90mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£136.92£164.30 Ex VATInc VAT£15.85£19.02 Per M2 Add to cart -

20mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 15 (43.20m2)

All three models 20mm Kingspan Therma PIR Insulation Board:

- 20mm Thermapitch TP10

- 20mm Thermafloor TF70

- 20mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

No longer in production.

£250.82£300.98 Ex VATInc VAT£5.81£6.97 Per M2 Get restock alert