Insulation Board

Insulation boards are the best way to increase the energy efficiency of residential and commercial buildings. They have excellent insulating capabilities while offering great value. By using them in a wide variety of spaces, including roofs, floors and walls, you can achieve improved thermal results cost-effectively and environmentally friendly.

What is Insulation Board?

Insulation board, also called rigid foam board, is used to obtain enhanced thermal insulation by eliminating heat loss in houses and business buildings.

Manufactured in various sizes and densities, they can be applied to multiple projects with unique requirements. Insulation sheets are light in weight, which facilitates you to handle them efficiently and versatile at your convenience.

Insulation panels are typically represented in polystyrene, rock wool or fibreglass, and polyisocyanurate (PIR). By having excellent thermal insulation characteristics, these insulation sheets allow you to increase indoor temperature resilience, which significantly cuts down utility prices. Furthermore, alongside their capabilities to innately resist moisture flourishing, many panels provide acoustic benefits by lessening the spread of noise movement.

Which insulation boards should you choose?

Before selecting insulation boards, consider all the requirements for your specific project needs. You can choose the best possible option depending on the following main criteria.

Cheap insulation board

The primary factor is your budget, as insulation sheets can widely vary in price and could be determined by their quantity. For example, our Polystyrene Insulation Boards have excellent quality characteristics while being more cost-effective than other types.

Is the insulation board waterproof and fire-resistant?

Whether the insulation board is waterproof or fire-resistant depends on the material type from which it is manufactured.

- Waterproof: Typically, panels from closed-cell foam, such as (EPS) Polystyrene Insulation Boards and (XPS) Extruded Polystyrene, resist moisture flourishing. A shallow water absorption rate can help you protect your building while taking proper protection and sealing measures.

- Fire-resistant: There can be several degrees of fire protection in insulation board characteristics. EPS and XPS insulation boards are typically designed with fire-resistance chemicals such as gypsum boards or intumescent coatings. At the same time, to comply with high-level safety regulations, you should ensure security requirements according to your building and manufacturer’s documentation.

Types of insulation boards

As we mentioned earlier, the insulation board choice depends on your project’s requirements. There is a wide range of insulation panels with different characteristics, but the following three types are the most common:

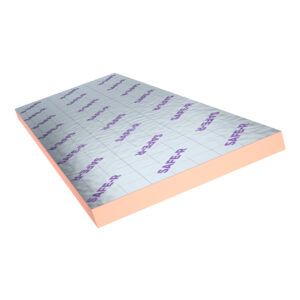

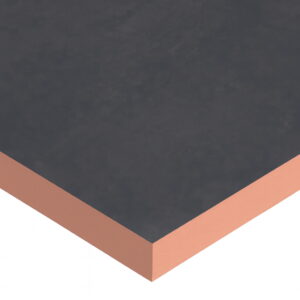

PIR insulation boards

Composed of polyisocyanurate foam, PIR insulation boards are utilised in most applications. Due to their capacity to significantly keep heat, they can be used as an additional layer to rigid thermal insulation made of polyurethane sheets. Many of our PIR insulation boards have a rigid PIR insulation core bonded between two foil sides and offer strong, light, and durable insulation.

Rigid phenolic insulation

Rigid phenolic panels are built on phenolic foam and have a high flame and thermal resistance level. This rigid insulation foam board is placed between two flexible layers and provides excellent efficiency and lower U values compared to PIR boards of the same thickness.

Expanded Polystyrene foam insulation (EPS)

Manufactured from expanded polystyrene beads, these sheets are lightweight and easy to install. Due to their characteristics, EPS boards are commonly used in specific areas, for example, to insulate basement walls. At Insulation Wholesale, we represent various insulation brands offering great value.

PIR Insulation

PIR insulation boards are rigid foam insulation panels used in construction. They provide significant benefits, such as excellent compressive strength, high thermal efficiency, moisture resistance, fire resistance, and adaptability. The ability of PIR insulation boards to reduce heat transmission offers energy efficiency and enhances building comfort. Therefore, they are applied to floors, walls and roofs to improve thermal insulation while optimising indoor convenience.

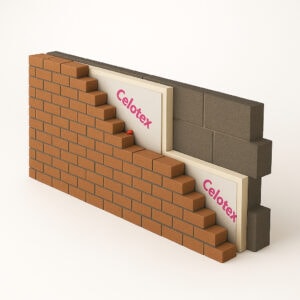

Celotex Insulation Board

Another rigid foam insulation board type, Celotex Insulation Board, is made from polyisocyanurate (PIR) foam. By offering excellent thermal insulation and being lightweight and fire-resistant, it can be used for a variety of purposes, including flooring, cavity walls, roofs, and walls. It comes in different sizes and thicknesses while delivering low emissivity and solid compressive strength and being compliant with relevant building regulations and standards.

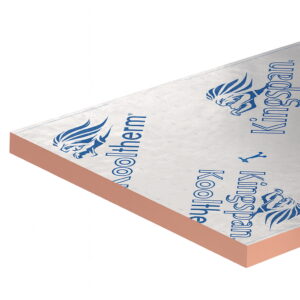

Kingspan Insulation Board

Kingspan Insulation Board is a well-known brand of rigid foam insulation boards used for thermal insulation in buildings. Manufactured from polyisocyanurate foam, phenolic foam, or expanded polystyrene, they offer outstanding thermal efficiency, reduce heat loss and enhance energy usage. They are appropriate for floors, cavity walls, roofs, and walls in residential and business buildings. These boards can be in different sizes and thicknesses while providing flexibility for various building needs.

Ecotherm Insulation Board

Ecotherm insulating boards are popular for their superior compressive strength, low weight, and simplicity of installation. They offer high dimensional stability and are perfect for residential, ground-supported, or suspended concrete slab ground floors. Eco-Versal, one of the best-known products of this brand, covered with an aluminium foil composite on both sides, offers complete building insulation solutions for various applications.

Unilin Insulation Board

Unilin Insulation, previously known as Xtratherm, specialises in insulation materials for the building sector. These boards have exceptional thermal insulation qualities and are lightweight, moisture-resistant, and often fire-resistant. Due to their characteristics, they can be helpful in both residential and commercial settings. Unilin Insulation is committed to sustainability and complies with all necessary construction codes and requirements.

Recticel Insulation Board

A leading business focusing on manufacturing insulation materials for the construction industry is Recticel Insulation Board. The selection of rigid foam insulation boards, made from minerals like polyisocyanurate (PIR) foam or polyurethane (PUR) foam, successfully protects against heat flow and helps residences preserve energy. These boards are often found in commercial and residential buildings and can be used for a wide range of purposes.

Mannok Insulation Board

Mannok Insulation Board, formerly Quinn Therm, produces high-performance insulation boards that can be applied in different environments. Made from expanded polystyrene (EPS) or polyisocyanurate (PIR) foam, they ideally prevent heat loss and significantly improve building energy efficiency. Thanks to their excellent thermal value, lightweight design, and durability, they can be used for insulating walls, roofs, floors, and pitched roofs.

IKO Insulation Board

IKO is a global leader in manufacturing rigid foam insulation boards. One of their most popular products, IKO Enertherm, is high-quality insulation boards suitable for multiple applications. Due to their excellent characteristics, including high thermal efficiency, durability, moisture and fire resistance, and ease of handling, they can be used for roofs, basements, floors, walls, cavity walls and many more. They come in different sizes and thicknesses and comply with relevant building regulations.

Polystyrene Insulation Board

Polystyrene Insulation Board is another type of rigid foam insulation board produced from expanded or extruded polystyrene foam. They are moisture-resistant, lightweight, and deliver great thermal protection. These boards are suitable for a wide range of applications, including walls, roofs, floors, and basements in residential, commercial, industrial, and agricultural buildings. Placed in compliance with building requirements, polystyrene insulation boards are a cost-effective option to enhance energy efficiency.

Again, it is crucial to consider all the factors of your particular project while covering building documentation and material specifications to ensure safety and efficiency.

How much is the insulation board and Where to buy it?

Before choosing the type of insulation boards and what price to pay for them, it is essential to consider the following criteria:

Brand and characteristics: the price of a particular insulation panel depends on the material from which it is produced, its thickness and its supplier. For example, if talking about the insulation boards mentioned above, EPS boards are generally considered the least expensive insulation boards. They will cost approximately £1,45 per square metre, whereas PIR insulation panels vary from £5 to£15 per square metre. Particularly, depending on the thickness, you will pay between £5 and £18 per square metre if you need XPS sheets.

Specialised online supplier: among one the perfect places to purchase insulation boards is Insulation Wholesale. Alongside the wide brand selection of provided products in our specialised online store, you are offered professional staff assistance to help you choose the best possible option for your project.

Our knowledgeable team members, coupled with excellent delivery services, can significantly help you select the right insulation boards with the best possible price on the market to achieve high-quality and cost-effective results.

How to install the insulation board?

The installation process of the insulation board can be different. It depends on the type and material characteristics of the panel and the surface where you will attach your insulation boards. Furthermore, ensuring that you are aligned with the building regulations requirements is crucial.

Generally speaking, adhesive bonding and mechanical fixes are two commonly used methods of fixing insulation boards to the wall.

Adhesive bonding includes the following steps:

- Clean the area and remove all the debris while ensuring the surface is dry.

- Measure and cut the insulation panels according to the manufacturer’s specifications regarding the particular type of insulation sheets.

- Choose the suitable bonding glue appropriate for your panel type and the surface on which you will install them.

- Accurately apply the glue directly to where the board will be fixed or straight to the back of the insulation board. Push the board tightly towards the surface, aligning it with the marked area while ensuring the glue is smoothly spread over the surface.

- Take additional security measures by using adhesive-compatible tapes, mechanical fasteners, or adhesive-backed strips, if needed.

- Ensure that the insulation boards are appropriately fixed and smoothly aligned while filling the possible gaps (if any) with insulation tape or sealant.

How to fix the insulation board to a wall?

Despite the adhesive bonding method mentioned above, you can also install insulation boards to a wall using mechanical fixings.

Mechanical fixings

As with the adhesive bonding approach, you should prepare your area and insulation boards by cleaning the surface and cutting the panels. Additionally, selecting the relevant glue and accurately placing sheets in the fixing area are similar.

Although, at this stage, you should secure insulation panels with mechanical fixings. This will help you to obtain additional support and prevent the insulation boards from moving. You can use plastic wall plugs, screws, or nails designed to fix insulation boards.

Finally, seal the joints that insulation boards may have between them or at their edges to prevent air leakage using the appropriate sealant.

Can you paint the insulation board?

In case you can’t cover your insulation foam boards with plaster cover, you are able to paint them by following these steps:

- To have a smooth finish, you should cover the insulation boards’ edges with some sandpaper.

- Paint the entire surface with two or three coats to properly cover the foam’s pores, and be careful with the spray gun to avoid paint leaking to the surface.

- To add more protection to the painting, apply a wax sealer when the paint has thoroughly dried.

While painting your insulation boards, make sure to protect yourself by wearing a face mask and gloves.

How to cut the insulation board?

Depending on the type of insulation panels and the material they are produced from, you can use different approaches and instruments to cut the insulation boards.

A sharp utility knife, a hand saw, powdered-metal saw blades, or a jigsaw can all be utilised, depending on the insulation sheets material being cut.

Notch the cutting edge several times with a sharp utility knife to obtain a straight, strong cut. Then attach the sheet across the score line once you have crafted it. You are advised to use a hand saw or saw blade to get thicker insulation.

When using a hand saw, make gradual and precise cuts with a fine-tooth saw blade. Additionally, you can use a jigsaw to produce exact amounts in the insulating board, particularly for cuts with bends or unusual shapes. Make sure to select a sharp blade appropriate in this case and put minimum pressure whilst cutting with a jigsaw.

Again, don’t forget to protect yourself; use safety glasses and gloves to avoid injuries while working with sharp edges.

Where to install the insulation board?

Insulation boards may be placed in multiple locations to increase heat transfer and energy savings. Listed below are some typical places for installing insulating panels:

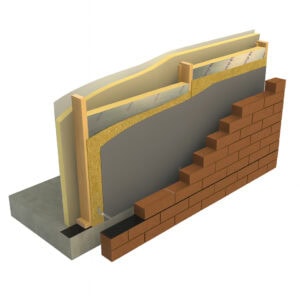

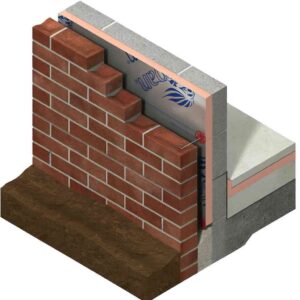

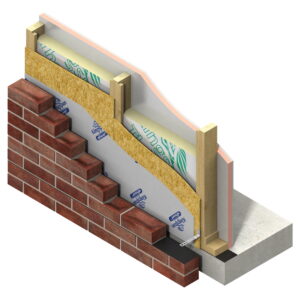

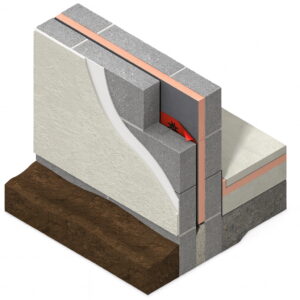

Walls

Insulation boards can be used while warming both interior and exterior walls. Coating walls within leads to improved thermal efficiency and less heat loss in a building. External wall insulation (EWI) is applied on the outside of the walls and enhances the building’s overall energy efficiency.

We recommend using plasterboards for interior walls, whereas, for exterior walls, we suggest insulation sheets with external-facing render.

While using insulation boards, you will ensure high U values and still get great interior space. Using small screws and wooden studs will reduce construction costs, especially considering that insulation panels typically serve longer than glass insulation.

Additionally, you can find a solution to the issue of gaps in your walls. Furthermore, if the boards have defects, they could be quickly covered to improve their thermal and airtightness performance.

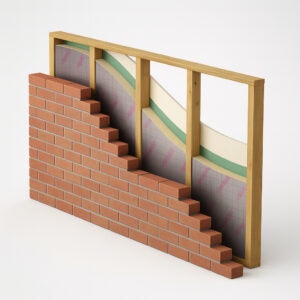

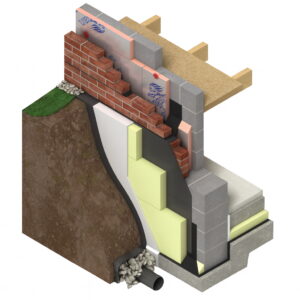

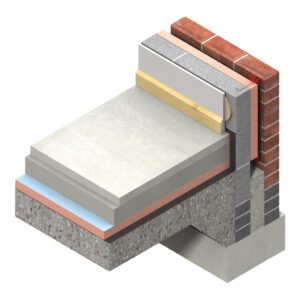

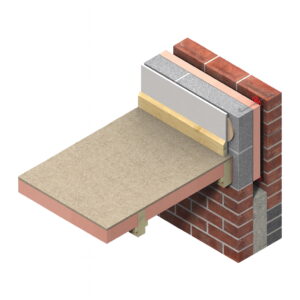

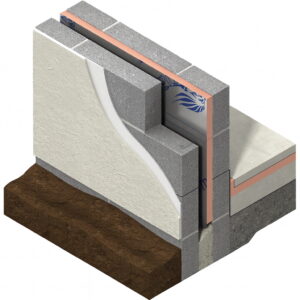

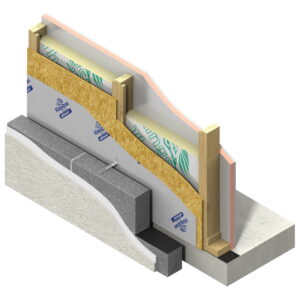

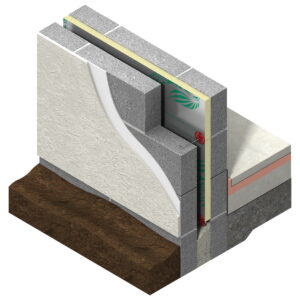

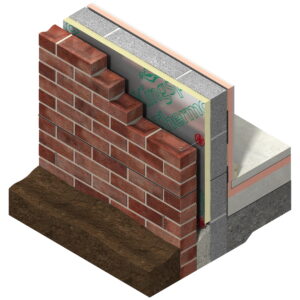

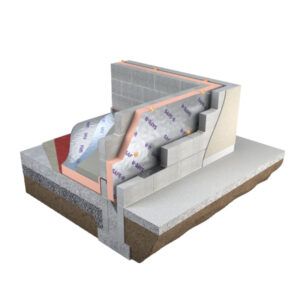

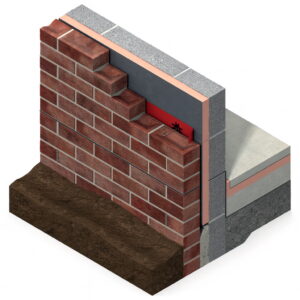

Cavity Walls

Most conventional buildings consist of an inner wall and an exterior wall. An opening separates the two walls.

An insulation panel is placed between the cavity’s two walls as a heat barrier. These two choices can be considered for new construction:

- Full cavity wall insulation is now available due to the creation of rigid insulation boards, which stop moisture flow.

- Partial fill cavity wall insulation is usually applied to block the rain seepage. Cavity closers seal any gaps after applying the insulation to the interior side while creating an open cavity.

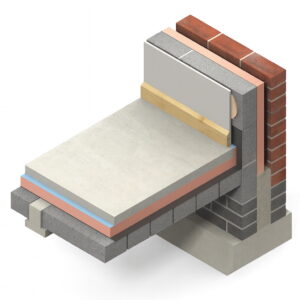

Floors

Floor insulation can drastically lower your energy utility costs. The outer edges of an uninsulated floor are where a significant amount of heat escapes. If you have a suspended wood floor, applying insulation between the joists is the most straightforward way to avoid losing heat. Typically, insulation is added under the floors and in between the wooden joists. Although it is worth mentioning that this process could take lots of time and usually is not a cheap project.

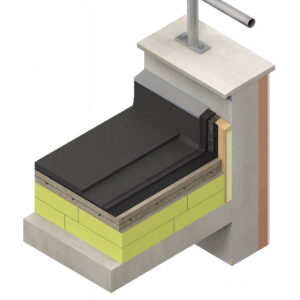

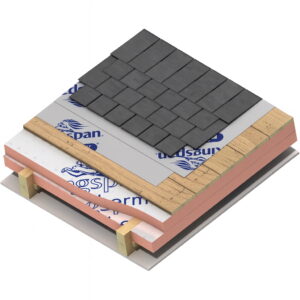

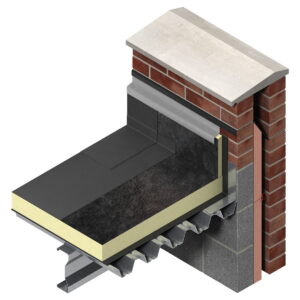

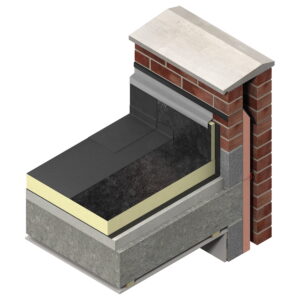

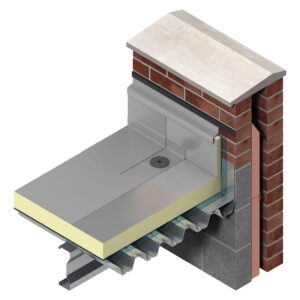

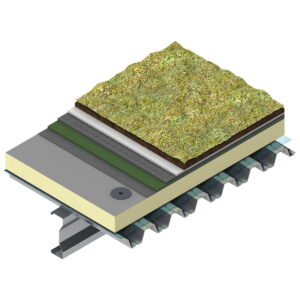

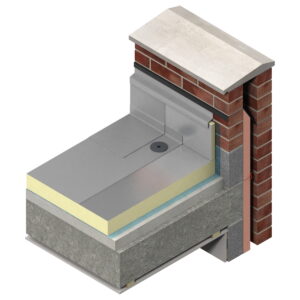

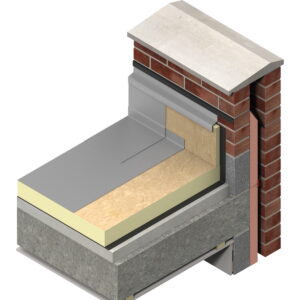

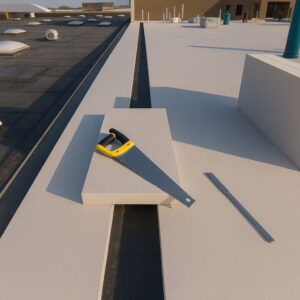

Flat Roofs

As insulation boards have excellent resistance to compression and can tolerate foot activity, they are typically applied to protect flat roofs.

Compression capacity is crucial, mainly if your flat roof is constructed of a single-ply material. Using the other materials puts you at risk of a water pool, which eventually causes leaks on the roof as they lack beneficial compression strength.

Pitched roofs

To prevent heat loss through the roof, insulation boards can be attached to the interior side of pitched roofs, between or above the roof rafters. Typically, this is referred to as loft insulation, which aids in preserving the appropriate temperature inside the building.

Conclusion

Insulation boards are an excellent way to increase heat retention and energy savings in residential and commercial buildings. Depending on their sizes, densities, and the material they are made of, you can apply them to walls, roofs, floors, cavity walls, and other places.

When selecting the correct type of insulating board, you should consider many factors, including its price, water and fire resistance capabilities. Alongside all this, while choosing the installation method, it is crucial to alight with your building safety regulations.

Our excellent team of experts in the construction field is the best choice for you to implement your project of any complexity. Please contact us at 0203 318 7316, and we can assist you in your journey.

-

Insulation Board By Thickness (368)

-

Floor Insulation Board (163)

-

Roof Insulation Board (220)

-

Wall Insulation Board (202)

-

Celotex Insulation Board (27)

-

Ecotherm Insulation Board (48)

-

IKO Insulation Board (14)

-

Kingspan Insulation Board (132)

-

Mannok Insulation Board (23)

-

PIR Insulation (210)

-

Polystyrene Insulation Board (50)

-

Recticel Insulation Board (62)

-

Unilin Insulation Board (26)

Showing 1–32 of 400 results

-

100mm Celotex CW4100 Cavity Wall Insulation Board 1200mm x 450mm 3.24m2 Pack of 6 (3.24m2)

100mm Celotex CW4100 Cavity Wall Insulation Board is an easy to install polyisocyanurate (PIR) insulation board with excellent thermal performance, featuring a low emissivity foil facing.

£43.34£52.01 Ex VATInc VAT£13.38£16.06 Per M2 Add to cart -

100mm Celotex GA4100 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Celotex GA4100 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£26.83£32.20 Ex VATInc VAT£9.32£11.18 Per M2 Add to cart -

100mm Ecotherm Eco-Versal Rigid PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Ecotherm Eco-Versal is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Ecotherm Eco-Versal is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£27.15£32.58 Ex VATInc VAT£9.43£11.32 Per M2 Add to cart -

100mm Expanded Polystyrene EPS100 Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 24 (69.12m2)

100mm EPS100, often known as Expanded Polystyrene, is a lightweight foam product produced from tiny polystyrene beads. Due to its high thermal value and simplicity of usage, it is commonly used as one of the most favoured insulation materials in construction.

£420.25£504.30 Ex VATInc VAT£6.08£7.30 Per M2 Add to cart -

100mm Expanded Polystyrene EPS150 Floor Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 6 (17.28m2)

100mm EPS150, often known as Expanded Polystyrene, is a lightweight foam product produced from tiny polystyrene beads. Due to its high thermal value and simplicity of usage, it is commonly used as one of the most favoured insulation materials in construction.

£159.72£191.66 Ex VATInc VAT£9.24£11.09 Per M2 Add to cart -

100mm Expanded Polystyrene EPS200 Floor Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 6 (17.28m2)

100mm EPS200, often known as Expanded Polystyrene, is a lightweight foam product produced from tiny polystyrene beads. Due to its high thermal value and simplicity of usage, it is commonly used as one of the most favoured insulation materials in construction.

£282.11£338.53 Ex VATInc VAT£16.33£19.60 Per M2 Add to cart -

100mm Expanded Polystyrene EPS250 Floor Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 6 (17.28m2)

100mm EPS250, often known as Expanded Polystyrene, is a lightweight foam product produced from tiny polystyrene beads. Due to its high thermal value and simplicity of usage, it is commonly used as one of the most favoured insulation materials in construction.

£374.89£449.87 Ex VATInc VAT£21.70£26.04 Per M2 Add to cart -

100mm Expanded Polystyrene EPS70 Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2 (Pack of 6)

100mm EPS70, often known as Expanded Polystyrene, is a lightweight foam product produced from tiny polystyrene beads. Due to its high thermal value and simplicity of usage, it is commonly used as one of the most favoured insulation materials in construction.

£93.00£111.60 Ex VATInc VAT£5.38£6.46 Per M2 Add to cart -

100mm Jablite HP+ 70E External Wall Insulation Board 1200mm x 600mm (4′ X 2′) Pack of 6 (4.32m2)

100mm Jablite HP+ 70E External Wall Insulation Board is designed to enhance thermal efficiency for external walls. It can be bonded or mechanically fixed, providing reliable insulation solution.

£39.82£47.78 Ex VATInc VAT£9.22£11.06 Per M2 Add to cart -

100mm Kingspan GreenGuard GG300 R Rigid Extruded Polystyrene Insulation Board 1250mm x 600mm Pack of 4 (3.00m2)

100mm Kingspan GreenGuard GG300 is a high performance rigid extruded polystyrene insulation. It is used to insulate inverted roofs, basements, car park decks, and heavy-duty commercial, industrial and cold store flooring offering a thermal conductivities as low as 0.033 W/mK.

£54.49£65.39 Ex VATInc VAT£18.16£21.79 Per M2 Add to cart -

100mm Kingspan Kooltherm K103 Insulation Floorboard 2400mm x 1200mm Pack of 3 (8.64m2)

100mm Kooltherm K103 is a premium phenolic core floor insulation solution, designed to deliver exceptional performance with solid concrete or suspended timber floors.

£289.93£347.92 Ex VATInc VAT£33.56£40.27 Per M2 Add to cart -

100mm Kingspan Kooltherm K107 Pitched Roof Board 2400mm x 1200mm Pack of 3 (8.64m2)

100mm Kingspan Kooltherm K107 Pitched Roof Board is a premium performance insulation with a fibre-free rigid thermoset phenolic core. It is used to insulate pitched roofs and attic spaces, and has a thermal conductivity of just 0.019 W/m.K across all thicknesses.

£288.66£346.39 Ex VATInc VAT£33.41£40.09 Per M2 Add to cart -

100mm Kingspan Kooltherm K108 Cavity Board Insulation 1200mm x 450mm Pack of 5 (2.70m2)

100mm Kingspan Kooltherm K108 partial fill cavity wall board is a premium performance lower lambda insulation with a rigid thermoset fibre-free phenolic core. It is faced on both sides with a low emissivity composite foil facing and is used in partially filled cavity walls.

£100.77£120.92 Ex VATInc VAT£37.32£44.78 Per M2 Add to cart -

100mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

All three models 100mm Kingspan Therma PIR Insulation Board:

- 100mm Thermapitch TP10

- 100mm Thermafloor TF70

- 100mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£138.93£166.72 Ex VATInc VAT£16.08£19.30 Per M2 Add to cart -

100mm Kingspan Thermaroof TR24 Flat Roof PIR Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Kingspan Thermaroof TR24 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. Kingspan Thermaroof is suitable for flat roofs waterproofed with partially bonded torch applied multi-layer bituminous waterproofing.

£88.77£106.52 Ex VATInc VAT£24.66£29.59 Per M2 Add to cart -

100mm Kingspan Thermaroof TR26 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

100mm Kingspan TR26 Thermaroof is high-performance insulation that has a fiber-free rigid thermoset polyisocyanurate (PIR) core. Suitable for flat roof application waterproofed with mechanically fixed single-ply waterproofing.

£187.40£224.88 Ex VATInc VAT£21.69£26.03 Per M2 Add to cart -

100mm Kingspan Thermaroof TR27 PIR Insulation Board 1200mm x 1200mm Pack of 4 (5.76m2)

100mm Kingspan Thermaroof TR27 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. It is used to insulate flat roofs waterproofed with fully adhered single-ply, partially bonded built-up felt, mastic asphalt and cold liquid applied waterproofing.

£127.81£153.37 Ex VATInc VAT£22.19£26.63 Per M2 Add to cart -

100mm Kingspan Thermawall TW50 PIR Insulation Board 1200mm x 450mm Pack of 5 (2.70m2)

100mm Kingspan Thermawall TW50 is a high performance insulation with thermal conductivity of 0.022 W/mK. Therma is a range of PIR insulation available in a range of thicknesses.£49.24£59.09 Ex VATInc VAT£18.24£21.89 Per M2 Add to cart -

100mm Recticel Eurothane Eurodeck Insulation Board 2400mm x 1200mm Pack of 4 (11.52m2)

100mm Eurothane® Eurodeck is compatible with mechanically fixed single-ply systems, benefiting from high compressive strength and excellent dimensional stability that ensures the flat surface finish required for optimum performance in new build and refurbishment projects. It is faced on both sides with a multi-layer coated aluminum foil.

£164.80£197.76 Ex VATInc VAT£14.31£17.17 Per M2 Add to cart -

100mm Recticel Eurothane GP PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Recticel Eurothane GP is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Recticel is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£26.05£31.26 Ex VATInc VAT£9.05£10.86 Per M2 Add to cart -

100mm Recticel Eurowall Partial Cavity Wall Insulation Board 1200mm x 450mm Pack of 10 (5.40m2)

100mm Recticel Eurowall Partial Cavity is an advanced thermal insulation panel tailored for use in cavity wall systems, delivering exceptional energy efficiency and robust performance.

£88.04£105.65 Ex VATInc VAT£16.30£19.56 Per M2 Add to cart -

100mm Recticel Powerdeck F Flat Roof Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Powerdeck F flat roof insulation board is compatible with multiple waterproofing systems, benefiting from high compressive strength and excellent dimensional stability. Both sides of Powerdeck F are faced with a mineral coated glass fleece.

£59.70£71.64 Ex VATInc VAT£16.58£19.90 Per M2 Add to cart -

100mm Recticel Powerdeck U Flat Roof Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Powerdeck U flat roof insulation board is a high performance rigid PIR insulation board for use in warm flat roofs with bituminous torch-on felt waterproofing systems. Both sides of Powerdeck U are faced with a bituminous coated glass fleece.

£63.90£76.68 Ex VATInc VAT£17.75£21.30 Per M2 Add to cart -

100mm Unilin Safe-R SR/CW Partial Fill Cavity Wall Phenolic Insulation Board 1200mm x 450mm Pallet of 120 (64.80m2)

100mm Unilin Safe-R SR/CW Partial Fill Phenolic Cavity Wall Insulation Board is a high-performance insulation product specifically designed to enhance the thermal efficiency of cavity wall systems.

POA Get a quote -

110mm Celotex XR4110 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Celotex XR4110 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.14£38.57 Ex VATInc VAT£11.16£13.39 Per M2 Add to cart -

110mm Ecotherm Eco-Versal Rigid PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Ecotherm Eco-Versal is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Ecotherm Eco-Versal is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£33.97£40.76 Ex VATInc VAT£11.80£14.16 Per M2 Add to cart -

110mm Kingspan Thermaroof TR26 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

110mm Kingspan TR26 Thermaroof is high-performance insulation that has a fiber-free rigid thermoset polyisocyanurate (PIR) core. Suitable for flat roof application waterproofed with mechanically fixed single-ply waterproofing.

£208.20£249.84 Ex VATInc VAT£24.10£28.92 Per M2 Add to cart -

110mm Recticel Eurothane Eurodeck Insulation Board 2400mm x 1200mm Pack of 3 (8.64m2)

110mm Eurothane® Eurodeck is compatible with mechanically fixed single-ply systems, benefiting from high compressive strength and excellent dimensional stability that ensures the flat surface finish required for optimum performance in new build and refurbishment projects. It is faced on both sides with a multi-layer coated aluminum foil.

£133.69£160.43 Ex VATInc VAT£15.47£18.56 Per M2 Add to cart -

110mm Recticel Eurothane GP PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Recticel Eurothane GP is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Recticel is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.14£38.57 Ex VATInc VAT£11.16£13.39 Per M2 Add to cart -

110mm Unilin Thin-R PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pallet of 21 (60.48m2)

110mm Unilin Thin-R PIR insulation is a foil faced, high-performance insulation solution that offers exceptional thermal efficiency and durability. This polyisocyanurate insulation board, formerly known as Xtratherm, is ideal for a range of applications, such as floors, pitched roofs, and walls.

POA Get a quote -

115mm Celotex Thermaclass Cavity Wall 21 Insulation Board 1190mm x 450mm Pack of 5 (2.67m2)

115mm Celotex Thermaclass Cavity Wall 21 is a PIR T&G insulation board designed for full-fill cavity wall applications. Low-emissivity foil facing provides versatility during installation, allowing for a 10mm residual cavity.

£86.07£103.28 Ex VATInc VAT£32.24£38.69 Per M2 Add to cart -

115mm Kingspan Kooltherm K106 Cavity Board Insulation 1200mm x 450mm Pack of 4 (2.16m2)

115mm Kingspan Kooltherm K106 Cavity Board is a premium performance insulation with a fibre-free rigid thermoset phenolic core with a thermal conductivity of just 0.019 W/mK across all thicknesses.

£100.25£120.30 Ex VATInc VAT£46.41£55.69 Per M2 Add to cart