PIR Insulation

The polyisocyanurate (PIR) Insulation board is one of the most popular construction materials, primarily used for pitched roofs, walls, and floors in domestic and industrial projects.

We stock the most desirable brands, including Ecotherm, Recticel, and Kingspan PIR insulation. These boards are available in various thicknesses from 20mm to 150mm. They deliver an excellent thermal conductivity of 0.022 W/mK across all thicknesses and boast superb compressive strength.

What Is PIR Insulation Board?

PIR foam is made through a chemical reaction that results in a closed-cell structure that traps gas. Because blowing agent gas has lower thermal conductivity than air, it is among the most energy-efficient insulating materials on the market.

The material’s low thermal conductivity, combined with its ease of handling and versatility in a variety of applications, has made it increasingly popular among architects and contractors.

The boards do not work on their own, though. Each piece of PIR is wrapped in a facing – usually a foil, a glass-tissue layer, or a bitumen-ready coating – and those facers do as much work as the foam itself. They control moisture, help the board bond to membranes, stiffen the panel, and can influence aspects of fire performance.

What Are PIR Insulation Panels Used For?

PIR insulation is suited to diverse applications:

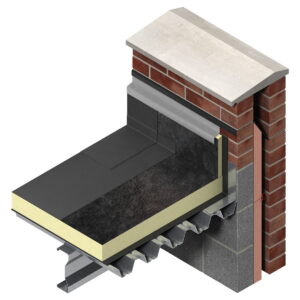

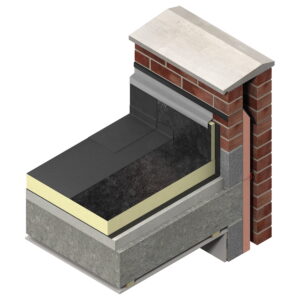

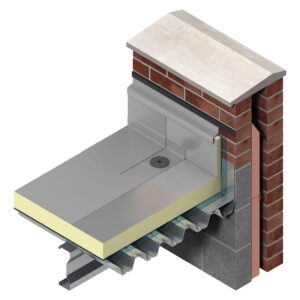

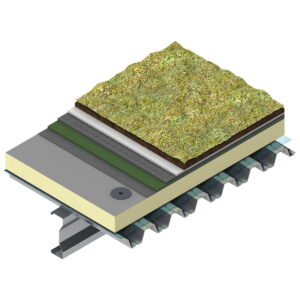

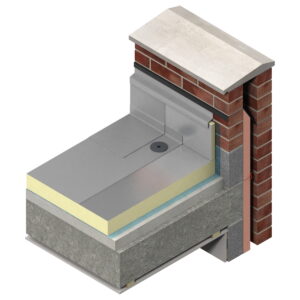

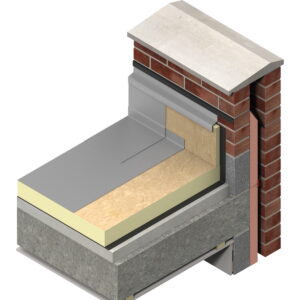

- Flat roofs. Bitumen-ready boards complement torch-on felt systems; glass-tissue boards are used under mechanically fixed single-ply or metal membranes.

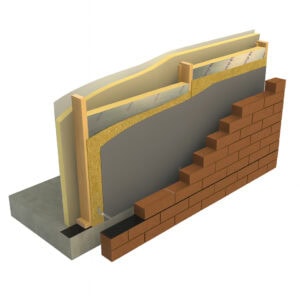

- Pitched roofs (between, under, or over rafters). Between rafters, it keeps the structure warm. Under rafters, it doubles as a vapour-control layer when foil-faced. Over rafters, it creates a continuous warm-roof layer with minimal thermal bridging.

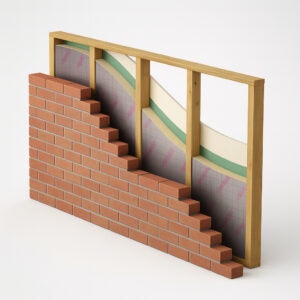

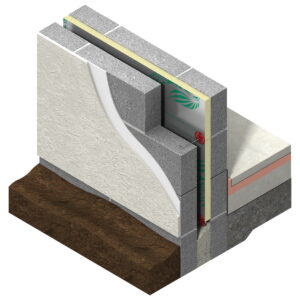

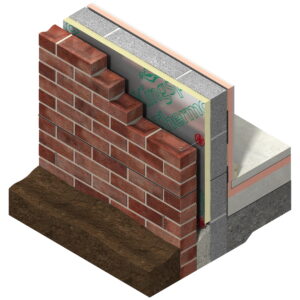

- Cavity walls. They are cut to fit neatly between wall ties and typically use reflective foil facers to boost performance in partial-fill systems.

- Ground floors and suspended timber floors. Used with concrete slabs, screeds, and timber joists.

- External wall systems, linings & special details. Often used in dry-lining boards (PIR bonded to plasterboard), insulated render systems, or warm balcony and threshold build-ups.

Types Of PIR Insulation Panels

PIR insulation panels can be grouped by application:

PIR for Flat Roofs

These are used on concrete, timber, or metal decks for warm roofs. Flat-roof PIR always needs facings that work with a membrane, so the facer type is a big deal here.

Common Facings in Flat-Roof PIR

a) Bitumen-coated glass-tissue facer

- Made for torch-on felt and multi-layer bituminous membranes.

- Usually topped with a polypropylene fleece to prevent slippage.

- Found on products like Kingspan TR24.

b) Glass-tissue (mineral-coated) facer

- Slightly tougher, used when the roofer wants improved stability under hot works.

- Compatible with adhesives and some mechanically fixed systems.

- An example is Kingspan TR27.

c) Foil facer (less common for roofs)

- Used mainly for fully adhered and single-ply roof finishes, or when designers want a reflective layer.

- Common on universal PIR boards, but not suitable for torch-on systems.

- Example Kingspan TR26 ( used only where permitted by the roofing system manufacturer).

PIR for Pitched Roofs (Between, Under, or Over Rafters)

These are used in loft conversions, attic refurbishments, warm pitched roofs, and dormer cheeks. They are moisture-tolerant, rigid, and easy to cut around rafters.

Common Facings in Pitched-Roof PIR

Foil-faced PIR (the standard)

- Aluminium foil on both sides.

- Acts as a built-in vapour control layer, convenient under rafters.

- Provides excellent thermal performance and a clean surface for taping joints.

Examples of Pitched-Roof PIR Boards

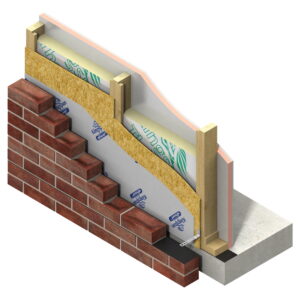

PIR for Cavity Walls (Masonry Construction)

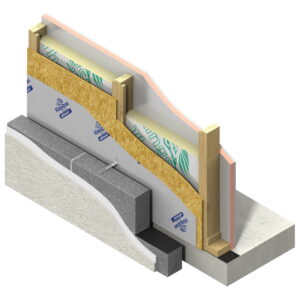

For new-build cavity walls, partial-fill, or full-fill, depending on design. They resist moisture ingress, fit neatly between wall ties, and prevent thermal bridging.

Common Facings in Cavity PIR

a) Foil facers (highly reflective)

- Most cavity-wall PIR systems have low-emissivity foil on both sides.

- Helps boost performance in the cavity airgap.

- Also provides moisture resistance.

b) Textured/embossed foil

- Some manufacturers use micro-patterned foil to improve adhesion or prevent sticking during installation.

c) Water-repellent coated facers

- Applied to full-fill boards to provide extra rain resistance during construction.

Examples of Cavity-Wall PIR Boards

- Celotex CW4000

- Kingspan Thermawall TW50 & TW55

- Recticel Eurowall Cavity

PIR for Floors (Screeded or Timber Suspended)

For ground floors, suspended timber floors, and refurb work where weight and compressive strength matter. Floor PIR has high compressive strength, resists moisture, and keeps thermal performance stable beneath screed.

Common Floor-PIR Facings

a) Foil facers (most common)

- Acts as a vapour barrier under screed but does not replace a DPM where required.

- Helps with taped joints and radon barrier compatibility.

b) Glass-tissue facers

- Used on boards designed for adhesive bed fixing or where foil interaction is not needed.

Examples of Floor PIR Boards

Benefits Of PIR Board Insulation

- PIR is lighter than mineral wool insulation for similar thermal performance.

- Easy to install – simple handling, straightforward application.

- Reduces heat loss.

- PIR insulation is thin, which means less material results in lighter structures and saves on building materials.

- The foil facings have a high water vapour resistance and will therefore provide significant resistance to water vapour transmission.

- Resistant to the damage caused by water vapour and mould.

- Excellent coverage – 2400 x 1200mm panel provides a coverage area of 2.88m².

- Manufactured using blowing agents with zero ODP and low GWP.

Why Choose Our PIR Boards?

We stock a full range of PIR boards from all the major brands – from everyday 25–150mm sheets right up to heavy-duty roof and floor specs, depending on the product.

We offer competitive PIR insulation prices for single boards, as well as wholesale, bulk, and trade discounts when you are loading up for a full job.

We provide fast dispatch, nationwide delivery, and dependable timescales.

Order your PIR boards today from Insulation Wholesale. We stock the full range, offer fast delivery across the UK, and make it easy to find the cheapest PIR insulation for walls, roofs, floors, or lofts.

FAQ

Where to buy PIR insulation?

You can buy PIR board insulation online from specialist insulation stores such as Insulation Wholesale. As a leading PIR insulation supplier, we stock a full range of panels for walls, floors, roofs, and lofts – from foil-faced wall panels to roof-ready boards and heavy-duty floor insulation. If you are budgeting for a project, our team can provide quick, accurate quotes so you know the current PIR insulation prices before you order.

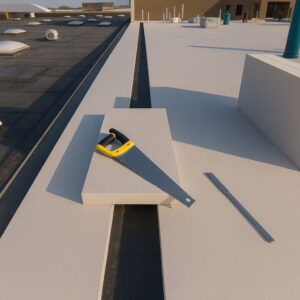

How to cut PIR insulation?

- Mark your cut line. Use a straightedge or long level. If your line is crooked, your cut will be too.

- Score the foil first. Take a sharp utility knife and lightly score along your line. This does not slice the board – it just breaks the foil, leaving a neat edge.

- Deepen the cut. Run your knife over the same line three or four times. You will feel it sink deeper each pass. For thinner boards (25–50mm), you can usually cut through the material with the knife alone.

- Snap the board. For thicker boards (75–150mm), once the knife has cut through the foil and a bit into the foam, tilt the board over an edge or your knee and snap it along the scored part. The core breaks cleanly.

- Trim the back. After snapping, the face will be clean-cut, and the back partially torn. Score the back foil with your knife and slice off the remaining foam.

- Optional: use a handsaw. If you prefer one tool start to finish, a fine-tooth handsaw works well. It is slightly messier but great for deep cuts or angled pieces.

How to install PIR insulation?

- Between Studs, Joists, or Rafters

This is the classic “cut to fit and friction-fix” method.

- Cut each board 3–5 mm wider than the gap.

- Fit it into the space so it grips the sides. That slight pressure keeps it snug.

- Make sure the face of the board sits flush with the timber so your plasterboard or internal lining lands cleanly.

- Tape the foil joints to get a tighter vapour barrier.

PIR is rigid enough to bridge the gap, and the foil face helps stop air movement. Always follow system-specific guidance for vapour control and ventilation requirements.

- Over Joists, Rafters, or Stud Walls (Continuous Layer)

This provides the best thermal performance by eliminating cold spots.

- Fix the boards directly over the timber using insulation fixings or long screws with washers.

- Stagger the joints so no straight lines run through the insulation.

- Tape all joints with foil tape to seal the layer.

- Fit your plasterboard or deck on top using long screws that reach the timber below.

The full sheet covers every timber, giving a more even thermal layer.

- Solid Masonry Walls (Internal Facing)

This is the “insulated lining board” approach.

- Dot-and-dab adhesive or mechanical fixings can be used, depending on the spec.

- Boards must sit flat with no steps between them.

- Tape joints, then add plasterboard over the top, or use insulated plasterboard that includes PIR.

It creates a warm internal surface and stops heat from bleeding into the cold wall.

- Floors

Most PIR in floors is installed under the screed or under a chipboard deck.

- Lay a DPM if needed.

- Put PIR boards tightly together with staggered joints.

- Tape where required, then add your screed or deck on top.

The rigid foam handles the load once it is supported by the layers above.

- Flat Roofs

Both warm-roof and inverted-roof setups commonly use PIR.

- Lay the boards over the roof deck.

- Stagger joints.

- Mechanically fix or bond, depending on the roof system.

- Add the waterproofing membrane over the top.

Can PIR insulation get wet?

PIR itself does not soak up water easily. So if the board gets a light splash or short-term exposure, it will not suddenly fall apart or lose its thermal performance. But it is not designed to stay wet because this can affect long-term stability. Long-term immersion or condensation behind the board can degrade facers or structure.

Can you use PIR insulation in loft?

Yes, PIR insulation works very well in a loft.

- Between Rafters

Fit PIR panels snugly between the rafters, leaving the required ventilation gap above – usually 25–50mm, depending on the roof. Seal small gaps with foam or tape to prevent cold bridges.

- Under Rafters (to boost U-value)

A continuous layer of foil-faced PIR is fixed across the underside of the rafters. This adds thermal performance, covers up imperfect cuts between rafters, and the foil layer acts as a vapour-control layer once joints are taped.

- Over Rafters (warm roof method)

If you are re-roofing, PIR slabs can be laid on top of the rafters before the breather membrane and tiles go on. This gives you a full warm roof with minimal thermal bridging – the most efficient loft system, but only practical during roof replacement.

-

125mm PIR Insulation (4)

-

20mm PIR Insulation (4)

-

25mm PIR Insulation (12)

-

30mm PIR Insulation (8)

-

40mm PIR Insulation (10)

-

50mm PIR Insulation (18)

-

60mm PIR Insulation (14)

-

70mm PIR Insulation (8)

-

75mm PIR Insulation (11)

-

80mm PIR Insulation (12)

-

90mm PIR Insulation (8)

-

100mm PIR Insulation (17)

-

110mm PIR Insulation (7)

-

115mm PIR Insulation (1)

-

120mm PIR Insulation (12)

-

130mm PIR Insulation (9)

-

140mm PIR Insulation (11)

-

150mm PIR Insulation (10)

-

165mm PIR Insulation (1)

Showing 1–32 of 210 results

-

100mm Celotex CW4100 Cavity Wall Insulation Board 1200mm x 450mm 3.24m2 Pack of 6 (3.24m2)

100mm Celotex CW4100 Cavity Wall Insulation Board is an easy to install polyisocyanurate (PIR) insulation board with excellent thermal performance, featuring a low emissivity foil facing.

£43.14£51.77 Ex VATInc VAT£13.31£15.97 Per M2 Add to cart -

100mm Celotex GA4100 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Celotex GA4100 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£26.67£32.00 Ex VATInc VAT£9.26£11.11 Per M2 Add to cart -

100mm Ecotherm Eco-Versal Rigid PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Ecotherm Eco-Versal is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Ecotherm Eco-Versal is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£26.67£32.00 Ex VATInc VAT£9.26£11.11 Per M2 Add to cart -

100mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

All three models 100mm Kingspan Therma PIR Insulation Board:

- 100mm Thermapitch TP10

- 100mm Thermafloor TF70

- 100mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£138.93£166.72 Ex VATInc VAT£16.08£19.30 Per M2 Add to cart -

100mm Kingspan Thermaroof TR24 Flat Roof PIR Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Kingspan Thermaroof TR24 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. Kingspan Thermaroof is suitable for flat roofs waterproofed with partially bonded torch applied multi-layer bituminous waterproofing.

£89.36£107.23 Ex VATInc VAT£24.82£29.78 Per M2 Add to cart -

100mm Kingspan Thermaroof TR26 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

100mm Kingspan TR26 Thermaroof is high-performance insulation that has a fiber-free rigid thermoset polyisocyanurate (PIR) core. Suitable for flat roof application waterproofed with mechanically fixed single-ply waterproofing.

£187.37£224.84 Ex VATInc VAT£21.69£26.03 Per M2 Add to cart -

100mm Kingspan Thermaroof TR27 PIR Insulation Board 1200mm x 1200mm Pack of 4 (5.76m2)

100mm Kingspan Thermaroof TR27 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. It is used to insulate flat roofs waterproofed with fully adhered single-ply, partially bonded built-up felt, mastic asphalt and cold liquid applied waterproofing.

£130.16£156.19 Ex VATInc VAT£22.60£27.12 Per M2 Add to cart -

100mm Kingspan Thermawall TW50 PIR Insulation Board 1200mm x 450mm Pack of 5 (2.70m2)

100mm Kingspan Thermawall TW50 is a high performance insulation with thermal conductivity of 0.022 W/mK. Therma is a range of PIR insulation available in a range of thicknesses.£49.24£59.09 Ex VATInc VAT£18.24£21.89 Per M2 Add to cart -

100mm Recticel Eurothane Eurodeck Insulation Board 2400mm x 1200mm Pack of 4 (11.52m2)

100mm Eurothane® Eurodeck is compatible with mechanically fixed single-ply systems, benefiting from high compressive strength and excellent dimensional stability that ensures the flat surface finish required for optimum performance in new build and refurbishment projects. It is faced on both sides with a multi-layer coated aluminum foil.

£163.45£196.14 Ex VATInc VAT£14.19£17.03 Per M2 Add to cart -

100mm Recticel Eurothane GP PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

100mm Recticel Eurothane GP is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Recticel is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£26.67£32.00 Ex VATInc VAT£9.26£11.11 Per M2 Add to cart -

100mm Recticel Eurowall Partial Cavity Wall Insulation Board 1200mm x 450mm Pack of 10 (5.40m2)

100mm Recticel Eurowall Partial Cavity is an advanced thermal insulation panel tailored for use in cavity wall systems, delivering exceptional energy efficiency and robust performance.

£82.13£98.56 Ex VATInc VAT£15.21£18.25 Per M2 Add to cart -

100mm Recticel Powerdeck F Flat Roof Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Powerdeck F flat roof insulation board is compatible with multiple waterproofing systems, benefiting from high compressive strength and excellent dimensional stability. Both sides of Powerdeck F are faced with a mineral coated glass fleece.

£59.13£70.96 Ex VATInc VAT£16.43£19.72 Per M2 Add to cart -

100mm Recticel Powerdeck U Flat Roof Insulation Board 1200mm x 600mm Pack of 5 (3.60m2)

100mm Powerdeck U flat roof insulation board is a high performance rigid PIR insulation board for use in warm flat roofs with bituminous torch-on felt waterproofing systems. Both sides of Powerdeck U are faced with a bituminous coated glass fleece.

£62.83£75.40 Ex VATInc VAT£17.45£20.94 Per M2 Add to cart -

110mm Celotex XR4110 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Celotex XR4110 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.42£38.90 Ex VATInc VAT£11.26£13.51 Per M2 Add to cart -

110mm Ecotherm Eco-Versal Rigid PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Ecotherm Eco-Versal is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Ecotherm Eco-Versal is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.42£38.90 Ex VATInc VAT£11.26£13.51 Per M2 Add to cart -

110mm Kingspan Thermaroof TR26 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 3 (8.64m2)

110mm Kingspan TR26 Thermaroof is high-performance insulation that has a fiber-free rigid thermoset polyisocyanurate (PIR) core. Suitable for flat roof application waterproofed with mechanically fixed single-ply waterproofing.

£212.43£254.92 Ex VATInc VAT£24.59£29.51 Per M2 Add to cart -

110mm Recticel Eurothane Eurodeck Insulation Board 2400mm x 1200mm Pack of 3 (8.64m2)

110mm Eurothane® Eurodeck is compatible with mechanically fixed single-ply systems, benefiting from high compressive strength and excellent dimensional stability that ensures the flat surface finish required for optimum performance in new build and refurbishment projects. It is faced on both sides with a multi-layer coated aluminum foil.

£133.69£160.43 Ex VATInc VAT£15.47£18.56 Per M2 Add to cart -

110mm Recticel Eurothane GP PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

110mm Recticel Eurothane GP is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Recticel is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.42£38.90 Ex VATInc VAT£11.26£13.51 Per M2 Add to cart -

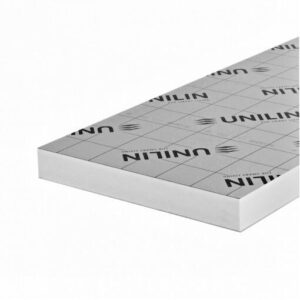

110mm Unilin Thin-R PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pallet of 21 (60.48m2)

110mm Unilin Thin-R PIR insulation is a foil faced, high-performance insulation solution that offers exceptional thermal efficiency and durability. This polyisocyanurate insulation board, formerly known as Xtratherm, is ideal for a range of applications, such as floors, pitched roofs, and walls.

POA Get a quote -

115mm Recticel Eurowall Full Fill Cavity Wall Insulation Board 1200mm x 460mm Pack of 8 (4.41m2)

115mm Recticel Eurowall Full Fill boards snap together with interlocking edges, forming a continuous thermal barrier that optimises performance of cavity wall insulation.

£97.54£117.05 Ex VATInc VAT£22.12£26.54 Per M2 Add to cart -

120mm Celotex XR4120 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

120mm Celotex XR4120 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.75£39.30 Ex VATInc VAT£11.37£13.64 Per M2 Add to cart -

120mm Ecotherm Eco-Versal Rigid PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

120mm Ecotherm Eco-Versal is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Ecotherm Eco-Versal is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.44£38.93 Ex VATInc VAT£11.26£13.51 Per M2 Add to cart -

120mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 120mm Kingspan Therma PIR Insulation Board:

- 120mm Thermapitch TP10

- 120mm Thermafloor TF70

- 120mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£111.30£133.56 Ex VATInc VAT£19.32£23.18 Per M2 Add to cart -

120mm Kingspan Thermaroof TR24 Flat Roof PIR Insulation Board 1200mm x 600mm Pack of 4 (2.88m2)

120mm Kingspan Thermaroof TR24 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. Kingspan Thermaroof is suitable for flat roofs waterproofed with partially bonded torch applied multi-layer bituminous waterproofing.

£80.59£96.71 Ex VATInc VAT£27.98£33.58 Per M2 Add to cart -

120mm Kingspan Thermaroof TR26 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

120mm Kingspan TR26 Thermaroof is high-performance insulation that has a fiber-free rigid thermoset polyisocyanurate (PIR) core. Suitable for flat roof application waterproofed with mechanically fixed single-ply waterproofing.

£142.77£171.32 Ex VATInc VAT£24.79£29.75 Per M2 Add to cart -

120mm Kingspan Thermaroof TR27 PIR Insulation Board 1200mm x 1200mm Pack of 4 (5.76m2)

120mm Kingspan Thermaroof TR27 is a high performance insulation with a fibre-free rigid thermoset polyisocyanurate (PIR) core. It is used to insulate flat roofs waterproofed with fully adhered single-ply, partially bonded built-up felt, mastic asphalt and cold liquid applied waterproofing.

£144.44£173.33 Ex VATInc VAT£25.08£30.10 Per M2 Add to cart -

120mm Recticel Eurothane Eurodeck Insulation Board 2400mm x 1200mm Pack of 4 (11.52m2)

- 120mm Eurothane® Eurodeck is compatible with mechanically fixed single-ply systems, benefiting from high compressive strength and excellent dimensional stability that ensures the flat surface finish required for optimum performance in new build and refurbishment projects. It is faced on both sides with a multi-layer coated aluminum foil.

£198.33£238.00 Ex VATInc VAT£17.22£20.66 Per M2 Add to cart -

120mm Recticel Eurothane GP PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

120mm Recticel Eurothane GP is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Recticel is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£32.44£38.93 Ex VATInc VAT£11.26£13.51 Per M2 Add to cart -

120mm Recticel Powerdeck F Flat Roof Insulation Board 1200mm x 600mm Pack of 4 (2.88m2)

120mm Powerdeck F flat roof insulation board is compatible with multiple waterproofing systems, benefiting from high compressive strength and excellent dimensional stability. Both sides of Powerdeck F are faced with a mineral coated glass fleece.

£55.50£66.60 Ex VATInc VAT£19.27£23.12 Per M2 Add to cart -

120mm Recticel Powerdeck U Flat Roof Insulation Board 1200mm x 600mm Pack of 4 (2.88m2)

120mm Powerdeck U flat roof insulation board is a high performance rigid PIR insulation board for use in warm flat roofs with bituminous torch-on felt waterproofing systems. Both sides of Powerdeck U are faced with a bituminous coated glass fleece.

£57.08£68.50 Ex VATInc VAT£19.82£23.78 Per M2 Add to cart -

125mm Kingspan Therma TP10 / TF70 / TW55 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) Pack of 2 (5.76m2)

All three models 20mm Kingspan Therma PIR Insulation Board:

- 125mm Thermapitch TP10

- 125mm Thermafloor TF70

- 125mm Thermawall TW55

share the same high-performance PIR core and low-emissivity foil facings, offering excellent thermal efficiency and easy installation. Although labeled differently, these boards share identical technical specifications.

£128.56£154.27 Ex VATInc VAT£22.32£26.78 Per M2 Add to cart -

130mm Celotex XR4130 PIR Insulation Board 2400mm x 1200mm (8′ x 4′) 2.88m2

130mm Celotex XR4130 is a polyisocyanurate (PIR) insulation core with composite aluminium foil facings on both sides. Celotex is a multi-purpose insulation board suitable for use in pitched roofs, ceilings, floors and walls.

£38.80£46.56 Ex VATInc VAT£13.47£16.16 Per M2 Add to cart