Plasterboard

Understanding that varying new build/ renovation projects require different types of plasterboard, Insulation Wholesale stocks a wide range of plasterboard sheets to meet all your project demands.

From a broad range of thicknesses with standard and ending with insulated plasterboards (9.5mm, 12.5mm, 15mm with standard plasterboard thicknesses to a whole 92.5mm of insulated plasterboard thicknesses) and varied lengths and widths, there are different sizes and thicknesses suitable for your project. Browse plasterboards by category or in the menu and find the specific products you need easily.

What is Plasterboard?

Also known as gypsum board, wall panel, drywall, or wallboard, plasterboard is among the world’s most used building materials. It is typically specified for interior and wall-ceiling cladding in both commercial and residential buildings.

However, despite being one of the most used building materials, many people misunderstand plasterboard.

Before its debut in the construction industry, builders used a similar material containing asbestos. However, when asbestos’s harmful effects on health were uncovered, plasterboard sheets became the ideal replacement.

The wallboard is manufactured from a gypsum core, faced on both sides with paper or heavy foil. The edges can either be slightly bevelled (tapered) or flat (square).

Benefits of Using Plasterboard

There are many benefits of using plasterboard in your home. First, the material offers a smooth finish in case you want to decorate it. Secondly, the material is lightweight. This makes it easy to handle. Thirdly, you can use it to design curved walls. Here are some more advantages:

- Easy to install – Installing plasterboard is simple. Its lightweight nature reduces handling risk and speeds up installation.

- Cost-effective for budget-conscious projects – if you are operating with a shoestring budget, plasterboard is the only way out. It’s cost-effective while maintaining a high construction standard.

- Low impact on the environment – Many plasterboards incorporate recycled gypsum and paper; recycled content varies by manufacturer.

- Fire-resistant – plasterboard variations, such as fire-resistant versions, offer excellent fire resistance. Gypsum, which is the main component of plasterboard, resists fire, and special additives added improve this feature.

- Easy to repair – plasterboards can be repaired easily, and no complicated tools are needed.

Types of Plasterboard

There are various types of plaster board. Here are popular types that we stock:

Moisture Resistant Plasterboard

Moisture resistant plasterboard contains additives that prevent moisture ingress. The additives are normally in the plasterboard’s core.

This type of plaster board is ideal for use in moisture-prone areas such as bathrooms and kitchens. You can also use it in sheltered areas for external soffits.

Acoustic Plasterboard

Acoustic plasterboard is meant to reduce sound transmission between rooms. To offer optimal sound reduction, this plasterboard tends to have a higher density compared to other drywalls.

12.5mm and 15mm are the most common thicknesses. This thickness is enough to reduce noise travelling through the walls and ceiling. You can also enhance its acoustic ability by reinforcing it with noise-resistant materials such as acoustic mineral rolls or acoustic mineral slabs.

Standard Plasterboard

Standard plasterboard comes with both tapered and square edges, with a common sizes of 8×4, 6×3, 9×4 . The board also has one white/grey face ideal for direct painting or wallpapering.

Insulated Plasterboard

Also known as thermal plaster board, insulated plasterboard is a common form of gypsum board. It is meant to retain the heat in the room. To accomplish this, a thermal insulation board is added to the back of the drywall.

These two are combined to create a single board (insulation plasterboard). It is one of the cost-effective ways to insulate your walls.

Fire-Rated Plasterboard

It comes with fire-resistance properties. However, fire resistance depends on the complete system, not the board alone.

Those with high fire performance ratings don’t catch fire entirely, while others can only resist fire for a specific duration. However, the minimum fire performance rating for plasterboard is typically 30 minutes to 2 hours, depending on the board and system of installation and manufacturers’ guidelines.

Square-Edge Plasterboard

Square-edge plasterboard has straight, clean edges all the way around. When two boards meet, the joint sits flush rather than forming a dip.

Because of that, it’s mainly used where the board will be fully skimmed with plaster or overboarded. A full coat is applied over the surface, so the joints disappear completely. This type of edging is commonly used on walls and ceilings, and in projects aiming for a traditional plaster finish.

The square-edge design is simple and reliable, made for a proper skim finish. Use it for:

- High-end and traditional finishes

- Renovations and older properties – it’s better for full skims and uneven surfaces.

Don’t use square-edge if:

- You’re not planning to fully skim the surface

- You want a quick tape-and-joint finish

- The job needs to be finished fast with minimal plaster

Square-edge boards leave a flat joint, so if you just tape and fill them, the joint usually shows. They’re great only when a full skim is part of the plan. No skim? Wrong board.

Tapered-Edge Plasterboard

Tapered-edge plasterboard has slightly thinned edges along the long sides. That shallow recess is there for one reason: jointing.

When boards are fixed side-by-side, the taper creates space for jointing tape and compound. Once filled and sanded, the surface appears flat, with the joint not standing proud.

Plasterboards with tapered edges are ideal for tape-and-joint systems, especially on ceilings and in larger areas that require speed and consistency.

This type of edge is built for efficiency – less plaster, faster finishing, and a smooth, paint-ready surface when done properly. Use it on:

- Ceilings, especially if covering large areas – jointing is quicker and avoids heavy plaster overhead.

- New-build houses & apartments – faster finishing, cleaner joints, lower labour costs.

Avoid tapered-edge if:

- The wall or ceiling will be fully skimmed anyway

- You’re working on small patch jobs where jointing isn’t practical

- You want a traditional plaster finish throughout

Tapered edges are designed for jointing. They can be skimmed, but the recess becomes pointless and can actually make the plasterer’s job harder.

Sound and Moisture Resistant Plasterboard

This is a special plasterboard built to do two jobs at once: block sound and handle a bit of moisture better than standard boards. One of the most readily available combined options is the British Gypsum Gyproc SoundBloc Moisture Resistant Tapered Edge Plasterboard.

- Sound control: The core is denser than normal plasterboard. When used on a wall or ceiling, it reduces airborne noise between rooms.

- Moisture resistance: It has additives in the gypsum core and special facing paper that provide a bit more moisture resistance than regular board. That doesn’t mean it stops water like tile backer board, but it’s good for humid or damp internal spaces like bathrooms, kitchens, utility rooms – especially where you still want a plasterboard finish.

- Tapered edges: The long edges are tapered so you can neatly join boards together with tape and compound, then skim or finish with paint or tiles.

Foil-Backed Plasterboard

Foil-backed plasterboard is standard plasterboard with a thin foil layer attached to serve as a vapour control layer (VCL). That does not make the board waterproof. It makes it vapour-resistant from the rear.

Foil-backed boards are used on:

- External walls

- Timber frame constructions

- Loft conversions

- Rooms with higher humidity

- Anywhere a separate polythene vapour barrier would otherwise be installed

- It’s especially common in timber frame and insulated stud systems, where vapour control is critical.

Foil-backed plasterboard is popular because it saves time. Instead of fixing a separate VCL membrane behind the plasterboard, you fit one board, and you’re done.

However, foil-backed plasterboard is not:

- A substitute for proper waterproofing in wet rooms

- A replacement for tanking systems behind showers

- A full air-tightness system, unless properly sealed at joints and edges

For them to work properly, joints and perimeter gaps should be taped or sealed so moisture can’t bypass the foil layer.

Plasterboard Brands: How They Compare

You can buy these plasterboard brands at Insulation Wholesale:

British Gypsum – Gyproc

British Gypsum’s Gyproc Wallboard is the most widely specified general-purpose plasterboard in the UK. It’s typically rated around 0.19 W/m·K for thermal conductivity and offers standard fire reaction (A2-s1,d0) and decent rigidity for walls, ceilings, and partitions.

- Excellent all-rounder board, easy to cut, hang, and finish.

- Fire performance is reliable for standard domestic and commercial linings.

- Thermal performance isn’t designed to add insulation, but it does not hinder it either.

- The denser SoundBloc variants (λ ~0.25 W/m·K) are there when you need improved acoustic performance. Higher λ reflects density, not insulation intent.

Gypfor

Gypfor boards tend to lean toward slightly higher thermal conductivity (~0.25 W/m·K) than standard Gyproc or Knauf boards.

Standard Gypfor boards are solid, reliable, basic plasterboards – good for everyday drywall work. They meet the same fire reaction standards (A2-s1,d0) but are not designed for high-end acoustic or fire system specs.

Gypfor Fire variants boost density and fire capability (good for corridors or separating walls) while keeping the same core conductivity.

Gypfor is often value-oriented. It meets basic performance targets but is not geared toward cutting-edge specs.

Knauf

Knauf plasterboards match almost exactly the same thermal and fire performance as British Gypsum standard boards (~0.19 W/m·K, A2-s1,d0).

- Highly consistent manufacturing quality – boards cut and finish predictably.

- Wide range covering standard, performance, moisture-resistant, acoustic, and insulated products.

The Thermal Laminate board with polystyrene has significantly lower conductivity (~0.038 W/m·K), because it’s bonded to insulation – that’s a different category from standard gypsum.

Knauf is a balanced mainstream choice with a strong insulated board lineup for when thermal performance matters.

Siniat

Siniat standard boards also sit around 0.19 W/m·K for thermal conductivity and fire reaction A2-s1,d0 — essentially a peer to British Gypsum and Knauf in baseline performance.

The brand tends to have a comprehensive core range and is often bundled with its own metal framing systems. Siniat also has its own thermal and acoustic systems if you step up from standard boards.

In the standard plasterboard space, Siniat’s offering is very similar technically to Gyproc and Knauf. The differences felt on site tend to be edge finish, density perception, and merchant availability rather than huge technical performance gaps.

Here’s a comparison table showing how these plasterboard brands compare on the important specs:

| Brand/Product | Thermal Conductivity (λ) | Density (approx.) | Fire Reaction | Edge Types | Primary Use/Notes |

| British Gypsum – Gyproc Wallboard | ~0.19 W/m·K | ~620–660 kg/m³ | A2-s1,d0 | T/E or S/E | Widely specified general-purpose board for walls and ceilings. Balanced performance and easy finishing. |

| British Gypsum – Gyproc SoundBloc | ~0.25 W/m·K | Higher density

(>800kg/m³) |

A2-s1, d0 (EN 520 Type D) | T/E | Denser core improves airborne sound reduction. Not intended for thermal insulation. |

| Gypfor Standard Plasterboard | ~0.25 W/m·K | ≥660 kg/m³ | A2-s1,d0 | T/E or S/E | Value-focused standard plasterboard for basic wall and ceiling linings. |

| Gypfor Fire Plasterboard | ~0.25 W/m·K | >800 kg/m³ | A2-s1,d0 | T/E or S/E | Increased density for improved fire performance in rated systems. |

| Knauf Standard Wallboard | ~0.19 W/m·K | ~660 kg/m³ | A2-s1,d0 | T/E | Comparable to Gyproc Wallboard in performance; consistent finish quality. |

| Knauf Thermal Laminate | ~0.038 W/m·K (laminate version) | varies (insulated) | Depends on the system | T/E | Plasterboard bonded to insulation (EPS/PIR/phenolic). Thermal performance comes from the insulation layer, not the gypsum. |

| Siniat Standard Board | ~0.19 W/m·K | (~640–700 kg/m³) | A2-s1,d0 | T/E or S/E | Technically comparable to Gyproc and Knauf; often used within full Siniat systems. |

Notes on the figures:

- λ (thermal conductivity) is the measure of how easily heat travels through the board – lower is better for insulation. Boards around 0.19 W/m·K are typical standard gypsum plasterboards; higher values like 0.25 W/m·K reflect denser cores (often for fire or sound performance).

- Density affects strength, acoustic performance, and how solid the board feels. Higher density usually means better rigidity and sound performance.

- Fire reaction A2-s1,d0 means limited combustibility, typical for plain gypsum boards.

- Edge types: they include T/E (Tapered Edge) for tape-and-joint finishes and S/E (Square Edge) for full skim plaster finishes.

Best plasterboard picks by job type

- Everyday domestic jobs where performance isn’t critical: All will work; choose based on price and availability.

- Spec-driven jobs: Any of the big three – Gyproc, Knauf, Siniat.

- Water-prone areas: All have moisture-resistant boards, but Gyproc and Knauf are very common.

- Acoustic or fire performance: Go with the big three and match the board to the system’s rating.

Tight budget with standard needs: Gypfor boards do the basics well and cost less.

Plasterboard Thicknesses

The plasterboards are supplied in these thicknesses:

9.5mm Plasterboard

This is a lightweight board.

Used on ceilings with closer joist or metal frame spacing (e.g. 400mm centres) and light-duty areas, especially in refurb jobs. It’s easier to lift, easier to fix overhead, and puts less strain on the ceiling structure.

It cannot be used everywhere because it’s weaker. It dents more easily and doesn’t perform well in terms of fire or sound. Fine for ceilings, but not great for walls that’ll get knocked about.

To fix 9.5mm plasterboard onto timber studs or joists:

The board is thin and light, so you don’t need long screws. Aim for at least 20mm penetration.

Use 25mm drywall screws (standard choice) or 30mm screws if you want extra bite.

Onto metal studs: Use 25mm fine-thread drywall screws.

Fine thread bites properly into metal studs and reduces the chance of spin-out.

Both 25mm drywall screws and 30mm drywall screws come in loose or collated variety, with coarse thread and fine thread options available.

12.5mm Plasterboard

This is the standard, everyday thickness. The base thickness from which most fire, moisture, and acoustic boards start.

It’s strong enough for walls, ceilings, partitions, and most domestic and commercial work.

It’s used because it gives a good balance of strength, performance, and cost.

To fix 12.5mm plasterboard onto timber studs / joists, use 32mm drywall screws (most common) or 38mm screws if timber is uneven or slightly warped.

Onto metal studs, use 25–32mm fine-thread drywall screws. 25mm works for single-layer boards; 32mm gives a bit more forgiveness.

12.5mm boards are heavier, so you need more depth into the timber to keep everything tight and flat. Aim for 25mm penetration into timber.

Insulation Wholesale stocks both loose drywall screws and collated drywall screws in 32mm and 38mm thicknesses appropriate for use on 12.5mm plasterboard.

15mm Plasterboard

This is where performance goes a notch higher. 15mm is usually specified instead of doubling up thinner boards.

15mm boards are heavier and denser, and are best for better fire resistance, sound insulation, or impact strength.

Common on separating walls, stairwells, corridors, and ceilings.

27mm Plasterboard

27mm is usually plasterboard bonded to insulation (like PIR). Instead of fixing the insulation and the board separately, you fix one board that does both jobs.

This thickness is common in internal wall insulation, especially in refurb projects where you can’t build out a full stud wall. It’s a good option when upgrading thermal performance on existing walls.

35mm Plasterboard

Same idea as 27mm, just more insulation.

35mm insulated plasterboard offers better thermal performance, so it’s used when you need to meet tighter energy targets or address colder external walls.

It saves space compared to a full-insulated stud system and is popular for retrofits and room upgrades.

48mm Plasterboard

This is heavy-duty insulated plasterboard.

It’s used on external-facing walls, solid masonry walls, or projects that aim to significantly improve energy efficiency without rebuilding the wall structure. Best for major thermal upgrades and energy-efficiency-focused refurb work.

It’s thicker, heavier, and more expensive, but it can transform a cold room.

27mm, 35mm, and 48mm are common insualted plasterboar thicknesses, however you can also find 50.5mm, 52.5mm, 57.5mm, 62.5mm, 72.5mm, 82.5mm and 92.5mm thicknesses , not plasterboard core thicknesses. The insulated boards are laminated and usually consist of 12.5mm plasterboard bonded to insulation (PIR, EPS, phenolic, etc.).

Bottom Line

For minor or major renovation projects, plaster board is a viable DIY project. Depending on your home’s needs, you can choose the ideal type of plaster board from the different types available in our store.

Plasterboard is easy to cut, but making holes requires some practice, as the process is delicate. Drywall dust irritates your eyes, so when cutting, consider wearing protective glasses.

For any questions or queries about plasterboard materials or product recommendations, feel free to call our team of experts on 0203 318 7316; they will be more than happy to help.

FAQ

Where to buy plasterboard in the UK?

Buy plasterboard directly from our store. Insulation Wholesale supplies quality plasterboard sheets from renowned brands such as Knauf, British Gypsum, and Gypfor, available nationwide. Order in bulk today and enjoy volume discounts and fast delivery to your site or residential address.

Can plasterboard be painted?

Yes, plasterboard can be painted once properly prepared.

- Fill uneven parts and sand all surface imperfections to create a smooth surface.

- Coat the surface with a diluted emulsion (mist coat) or a specialist drywall primer to create a consistent base.

- Allow the base coat to dry fully.

- Apply the first layer of paint evenly and allow it to dry.

- Add the final layer of paint.

Can plasterboard get wet?

Yes, plasterboard can get wet. Once saturated with water, the board is likely to become damaged. Only moisture-resistant plasterboard sheets are water-repellent; regular plasterboard is not.

How much plasterboard do I need?

Larger spaces require more sheets while smaller areas need fewer. Manufacturers usually state the coverage area for each sheet of plasterboard. So you can calculate how many pieces you require for each space.

How to cut plasterboard?

Plasterboard can be cut easily and doesn’t require complicated tools. However, you can opt for more costly tools if you want.

The basic tools you need to cut plaster board are; a sharp knife (preferably a Stanley knife), a tape measure, an old saw, and a straight edge. You may also require a wallboard saw. Since Gypsum boards are heavy, you may need a second pair of hands to help you hold it when cutting.

- Step 1: Score one side of the drywall, then bend the part you want to cut in the opposite direction.

- Step 2: Cut along the folded edge with a sharp knife, and the two parts will separate easily on their own.

To cut plasterboard along its length, you will need a plasterboard saw. If you want to remove that part you have cut, score the side and use a knife following the first and second step.

To cut a hole, you would need to score the plaster board with a knife and knock the scored piece out using a hammer. However, it is not as easy as said here; it takes practice. Work carefully to avoid damaging the board.

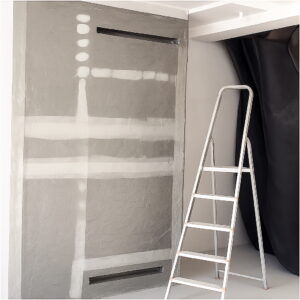

How to fix the plasterboard

- Measure and cut the panels to size.

- Ensure all timber or metal studwork is securely fixed.

- If adding insulation, slot it between the studs before installing the boards.

- Position each plasterboard sheet with the finished face outward. Butt the edges closely, leaving no spaces between them.

- Fasten the sheets with drywall screws, ensuring even spacing throughout.

- Apply joint tape and compound, then sand the surface smooth, ready for skimming or decoration.

-

British Gypsum Plasterboard (23)

-

Square Edge Plasterboard (7)

-

Standard Plasterboard (20)

-

Acoustic Plasterboard (17)

-

Fire Rated Plasterboard (12)

-

Moisture Resistant Plasterboard (11)

-

Tapered Edge Plasterboard (31)

-

Knauf Plasterboard (12)

-

Gypfor Plasterboard (19)

-

Siniat Plasterboard (8)

-

Foil Backed Plasterboard (4)

-

9.5mm Plasterboard (4)

-

12.5mm Plasterboard (36)

-

15mm Plasterboard (26)

Showing 1–32 of 73 results

-

12.5mm British Gypsum Gyproc F Multiboard 2400mm x 1200mm (8′ x 4′) 2.88m2

12.5mm Glasroc F Multiboard is a high-performance, moisture- and fire-resistant gypsum board reinforced with glass fibers, making it a durable choice for demanding environments like fire-rated partitions and ceilings.

£94.02£112.82 Ex VATInc VAT£32.65£39.18 Per M2 Add to cart -

12.5mm British Gypsum Gyproc Fireline Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm British Gypsum Gyproc Fireline Plasterboard is crafted to boost fire resistance in walls and ceilings. Its strong core and smooth finish ensure protection and easy installation for safety-focused projects.

£15.40£18.48 Ex VATInc VAT£5.35£6.42 Per M2 Add to cart -

12.5mm British Gypsum Gyproc Moisture Resistant Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm British Gypsum Gyproc Moisture Resistant Plasterboard is perfect for humid areas, with a water-resistant core and smooth, durable finish.

£19.68£23.62 Ex VATInc VAT£6.83£8.20 Per M2 Add to cart -

12.5mm British Gypsum Gyproc SoundBloc Moisture Resistant Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm British Gypsum Gyproc SoundBloc Moisture Resistant Plasterboard combines enhanced sound insulation with moisture resistance, offering a robust and versatile solution for controlling noise and tackling damp conditions in one smart panel.

£23.89£28.67 Ex VATInc VAT£8.30£9.96 M2 Add to cart -

12.5mm British Gypsum Gyproc SoundBloc Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm British Gypsum SoundBloc Plasterboard minimises noise transmission, making it perfect for creating quieter spaces.

£17.06£20.47 Ex VATInc VAT£5.92£7.10 M2 Add to cart -

12.5mm British Gypsum Gyproc Wallboard Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm British Gypsum Gyproc Wallboard is a durable, easy-to-install plasterboard ideal for interior walls and ceilings.

£11.89£14.27 Ex VATInc VAT£4.13£4.96 M2 Add to cart -

12.5mm Gypfor Fire Plasterboard Square Edge 1800mm x 900mm (6′ x 3′) Pallet of 72 Boards

12.5mm Gypfor Fire Plasterboard is suitable for interior drywall applications. In its composition are added additives that give it greater resistance to fire than other boards.

£539.43£647.32 Ex VATInc VAT£7.29£8.75 Per Sheet Add to cart -

Buy in Bulk & Save

1-30 31-125 126+ £12.56£15.07 £12.37£14.84 £12.25£14.70 BUY 42+ GET 5% OFF METAL

12.5mm Gypfor Fire Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Gypfor Fire Plasterboard is suitable for interior drywall applications. In its composition are added additives that give it greater resistance to fire than other boards.

£12.56£15.07 Ex VATInc VAT£4.36£5.23 M2 Add to cart -

Buy in Bulk & Save

1-30 31-125 126+ £14.44£17.33 £14.22£17.06 £14.01£16.81 BUY 42+ GET 5% OFF METAL

12.5mm Gypfor Moisture Resistant Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Gypfor Moisture Resistant Plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, designed to meet general construction requirements. Plasterboard composed of a non-combustible gypsum core, specially formulated, moisture- and mold-resistant, integrally involved in coating paper, color green. The product is ready for a variety of treatments and finishes after adequate surface preparation.

£14.44£17.33 Ex VATInc VAT£5.01£6.01 M2 Add to cart -

12.5mm Gypfor Moisture Resistant Plasterboard Tapered Edge 2700mm x 1200mm (9′ x 4′) Pallet of 42

12.5mm Gypfor Moisture Resistant Plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, designed to meet general construction requirements. Plasterboard composed of a non-combustible gypsum core, specially formulated, moisture- and mold-resistant, integrally involved in coating paper, color green. The product is ready for a variety of treatments and finishes after adequate surface preparation.

£510.00£612.00 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

1-30 31-125 126+ £11.88£14.26 £11.70£14.04 £11.58£13.90 BUY 42+ GET 5% OFF METAL

12.5mm Gypfor Soundproof Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Gypfor Soundproof plasterboard (commonly known as acoustic plasterboard) is a version of standard plasterboard and contains a strong level of sound insulation, thanks in large part to its density.

£11.88£14.26 Ex VATInc VAT£4.13£4.96 M2 Add to cart -

Buy in Bulk & Save

1-30 31-125 126+ £12.28£14.74 £12.10£14.52 £11.91£14.29 BUY 42+ GET 5% OFF METAL

12.5mm Gypfor Vapour Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Gypfor Vapour plasterboard is suitable for interior drywall applications in areas of humidity. 12.5mm Gypfor plasterboard is composed of a non-combustible gypsum core, and grey paper on the front face.

£12.28£14.74 Ex VATInc VAT£4.26£5.11 M2 Add to cart -

12.5mm Gypfor WallBoard Plasterboard Square Edge 1800mm x 900mm (6′ x 3′) Pallet of 90 Boards

12.5mm Standard Gypfor plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, designed to meet general construction requirements.

£550.37£660.44 Ex VATInc VAT£6.12£7.34 Per Sheet Add to cart -

12.5mm Gypfor WallBoard Plasterboard Square Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Standard Gypfor plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, designed to meet general construction requirements.

£8.22£9.86 Ex VATInc VAT£2.85£3.42 M2 Add to cart -

Buy in Bulk & Save

1-41 42+ £8.22£9.86 £7.97£9.56 BUY 42+ GET 5% OFF METAL

12.5mm Gypfor WallBoard Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Standard Gypfor plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, and designed to meet general construction requirements.

£8.22£9.86 Ex VATInc VAT£2.85£3.42 M2 Add to cart -

12.5mm Gypfor WallBoard Plasterboard Tapered Edge 2700mm x 1200mm (9′ x 4′)

12.5mm Standard Gypfor plasterboard is suitable for indoor applications, available in various thicknesses and longitudinal edge finishes, designed to meet general construction requirements.

£9.51£11.41 Ex VATInc VAT£3.30£3.96 M2 Add to cart -

12.5mm Knauf Fire Panel Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Fire Panel Plasterboard offers superior fire protection. The additional fire protection properties enable Knauf Fire plasterboard to be used where increased fire performance is required such as in domestic separating walls, garages and corridors. When used as part of a Knauf system, Fire Panel will give up to 120 minutes of fire protection.

£12.56£15.07 Ex VATInc VAT£4.36£5.23 M2 Add to cart -

12.5mm Knauf Moisture Panel Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Moisture Panel Plasterboard is a high performance moisture resistant plasterboard for use in internal areas of high humidity such as kitchens and bathrooms. Knauf moisture resistant plasterboard is ideal for receiving a plaster finish or for direct decoration.

£15.24£18.29 Ex VATInc VAT£5.29£6.35 M2 Add to cart -

12.5mm Knauf Sound Panel Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Sound Panel Plasterboard offers enhanced levels of sound performance and a greater density, making it ideal acoustic plasterboard for residential applications or where a minimum of 10kg/m2 is required. Knauf Sound Plasterboard is ideal for use in conjunction with Robust Details. Part E compliant.

£12.71£15.25 Ex VATInc VAT£4.41£5.29 M2 Add to cart -

12.5mm Knauf Soundshield Plus Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Soundshield Plus Plasterboard offers enhanced acoustic performance, excellent fire resistance and a severe duty impact rating. When Knauf plasterboard is used as part of a Knauf system, Soundshield Plus acoustic plasterboard will give up to 54 Db (Rw) acoustic sound reduction which makes it ideal for use in high traffic areas such as schools and hospitals.

£14.55£17.46 Ex VATInc VAT£5.05£6.06 M2 Add to cart -

12.5mm Knauf Vapour Panel Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Vapour Panel Plasterboard has a metallised polyester foil laminated on the grey paper face, making this laminated Knauf plasterboard resistant to vapour.

£14.50£17.40 Ex VATInc VAT£5.03£6.04 M2 Add to cart -

12.5mm Knauf Wallboard Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Knauf Wallboard Plasterboard ideally suits to receive a plaster finish, or for direct decoration. Knauf standard plasterboard will meet all basic drylining requirements, it is strong, versatile, and good value.

£8.93£10.72 Ex VATInc VAT£3.10£3.72 M2 Add to cart -

12.5mm Siniat GTEC Moisture Board Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

The 12.5mm Siniat GTEC Moisture Board is specifically designed to withstand high humidity areas,protecting against moisture damage. Its moisture-resistant core and durable surface make it an ideal solution for maintaining the longevity and safety of your building in challenging environments.

£15.13£18.16 Ex VATInc VAT£5.25£6.30 M2 Add to cart -

12.5mm Siniat GTEC dB Sound Board Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Siniat GTEC dB Sound Board minimizes noise transfer between walls and rooms. Its durable, high-performance design makes it a top choice for creating quieter and more comfortable environments at home or in commercial settings.

£14.55£17.46 Ex VATInc VAT£5.05£6.06 M2 Add to cart -

12.5mm Siniat GTEC Fire Board Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Siniat GTEC Fire Plasterboard is a high-performance solution for improving fire safety with limited combustibility in walls and ceilings. Its durability and straightforward installation makes it a practical choice for both professionals and DIY projects.

£13.97£16.76 Ex VATInc VAT£4.85£5.82 M2 Add to cart -

12.5mm Siniat GTEC Standard Board Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

12.5mm Siniat GTEC Standard Plasterboard is a reliable choice for creating smooth, sturdy walls and ceilings in interior spaces. It’s easy to handle and install thanks to its lightweight design, yet strong enough to ensure a durable and high-quality finish.

£9.08£10.90 Ex VATInc VAT£3.15£3.78 M2 Add to cart -

15mm British Gypsum Gyproc Fireline Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm British Gypsum Gyproc Fireline Plasterboard is crafted to boost fire resistance in walls and ceilings. Its strong core and smooth finish ensure protection and easy installation for safety-focused projects.

£18.65£22.38 Ex VATInc VAT£6.48£7.78 M2 Add to cart -

15mm British Gypsum Gyproc Moisture Resistant Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm British Gypsum Gyproc Moisture Resistant Plasterboard is perfect for humid areas, with a water-resistant core and smooth, durable finish.

£25.17£30.20 Ex VATInc VAT£8.74£10.49 M2 Add to cart -

15mm British Gypsum Gyproc SoundBloc Moisture Resistant Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm British Gypsum Gyproc SoundBloc Moisture Resistant Plasterboard combines enhanced sound insulation with moisture resistance, offering a robust and versatile solution for controlling noise and tackling damp conditions in one smart panel.

£30.15£36.18 Ex VATInc VAT£10.47£12.56 M2 Add to cart -

15mm British Gypsum Gyproc SoundBloc Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm British Gypsum SoundBloc Plasterboard minimises noise transmission, making it perfect for creating quieter spaces.

£20.46£24.55 Ex VATInc VAT£7.10£8.52 M2 Add to cart -

15mm British Gypsum Gyproc Wallboard Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm British Gypsum Gyproc Wallboard is a durable, easy-to-install plasterboard ideal for interior walls and ceilings.£14.72£17.66 Ex VATInc VAT£5.11£6.13 M2 Add to cart -

Buy in Bulk & Save

1-35 36-95 96+ £13.11£15.73 £12.91£15.49 £12.78£15.34 BUY 36+ GET 5% OFF METAL

15mm Gypfor Fire Plasterboard Tapered Edge 2400mm x 1200mm (8′ x 4′)

15mm Gypfor Fire Plasterboard is suitable for interior drywall applications. In its composition are added additives that give it greater resistance to fire than other boards.

£13.11£15.73 Ex VATInc VAT£4.55£5.46 M2 Add to cart